Application

An operator hit an obstruction in the lateral section of a well while attempting to pump down a gun string to perforate the first stage. The obstruction was close to the heel, so it would prevent fracturing of the entire lateral. After they could not easily resolve the obstruction, the operator called in DarkVision to understand what was preventing wireline from reaching depth.

Objectives Achieved

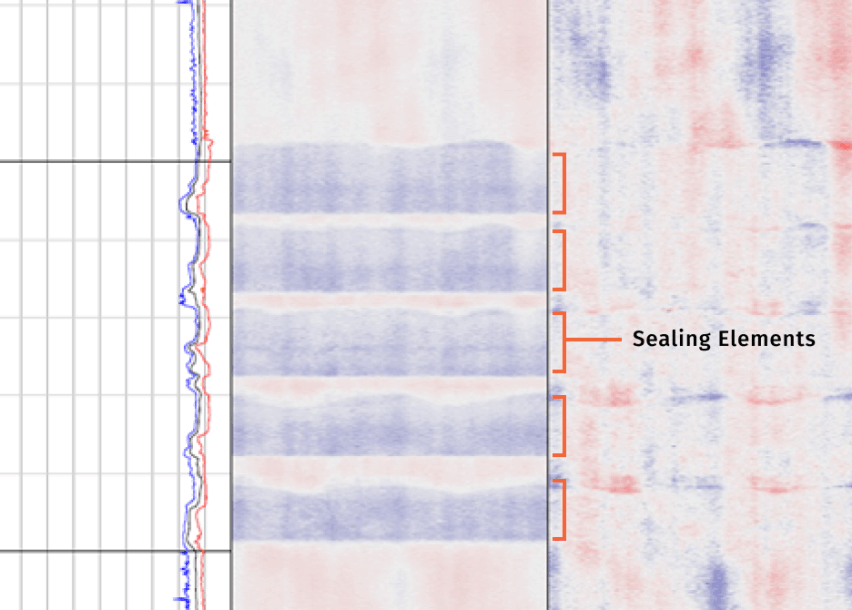

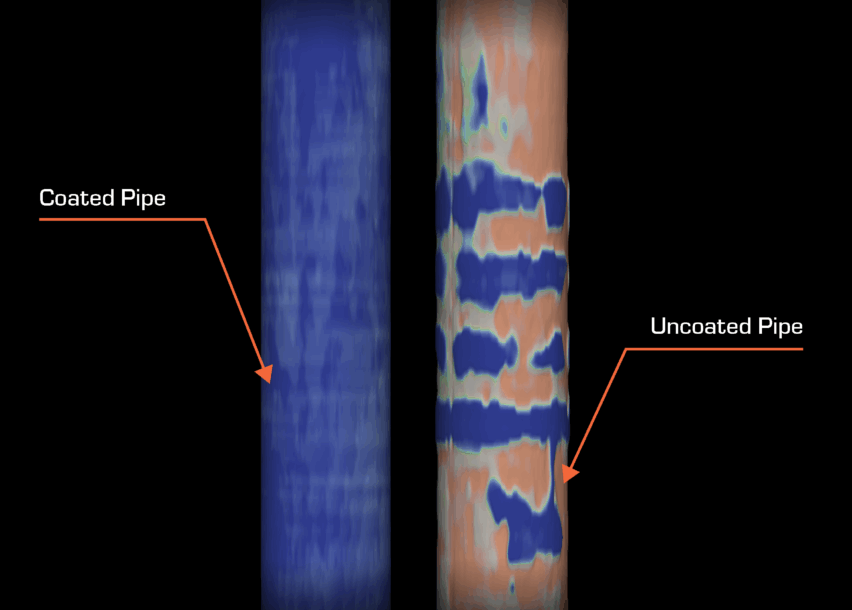

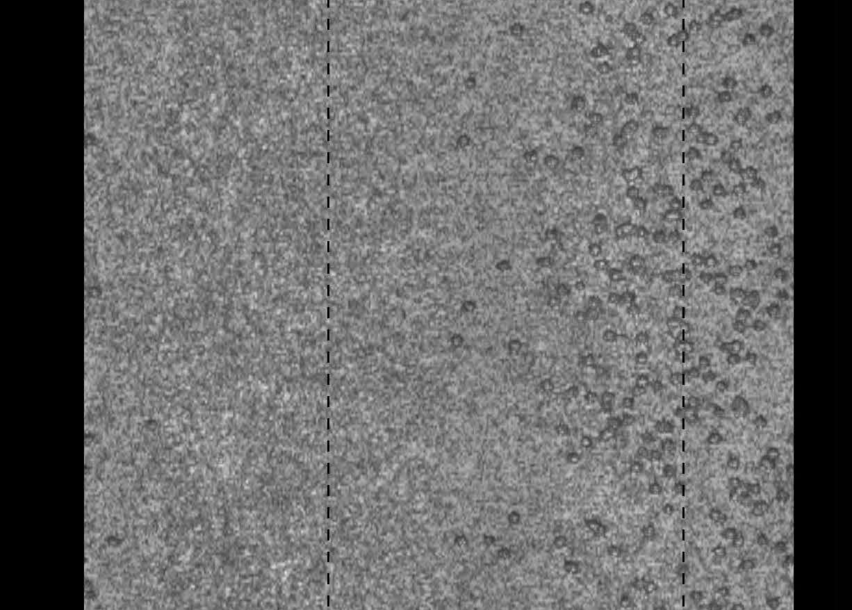

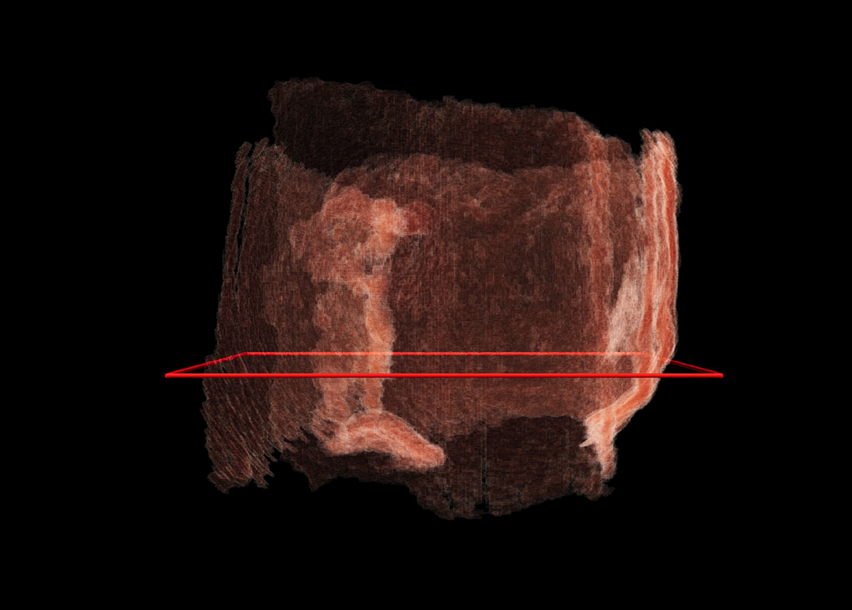

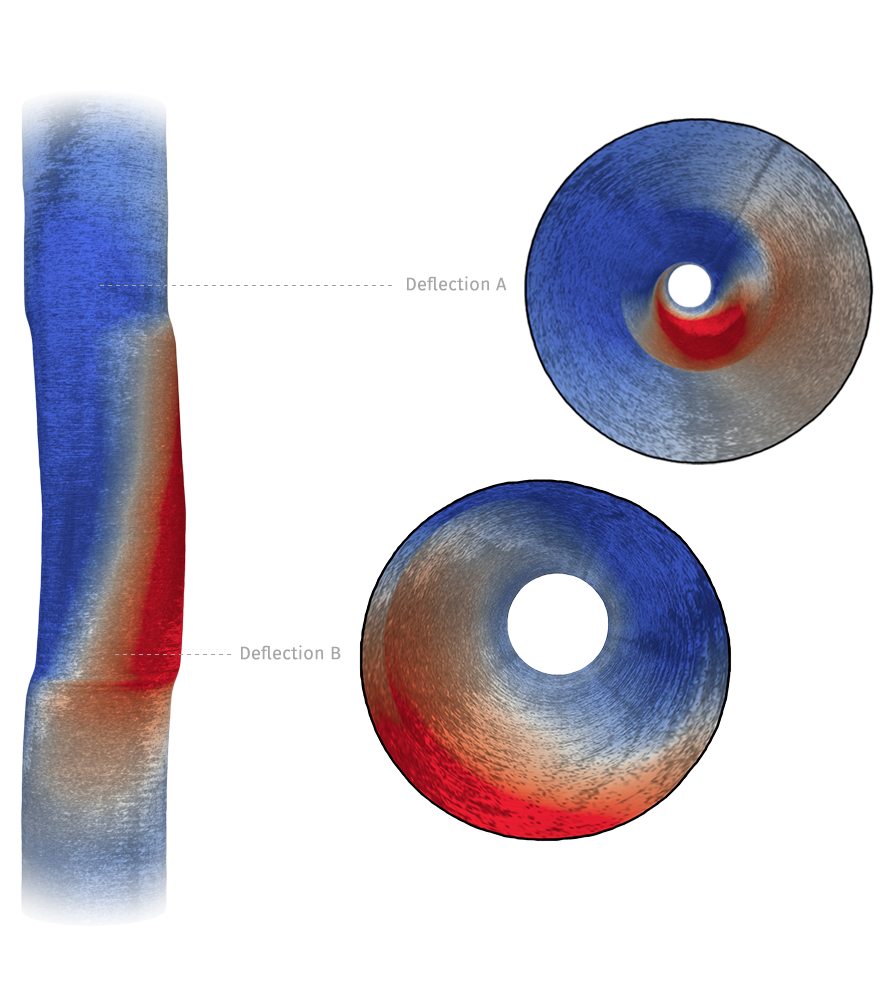

The operator ran HADES-R on coiled tubing which was already in the well. The tools were able to pass the obstruction and image the entire lateral. DarkVision’s imaging revealed that the obstruction was caused by three consecutive deflections in alternating directions. The deflections were so severe that it was not possible to pass them on wireline.

Results

The operator was surprised by DarkVision’s imaging results. They had assumed the issue was a physical obstruction that could be milled out, such as a restriction from an over torqued collar, and had not considered deflected casing as a potential cause.

Without knowing the cause of the obstruction, the operator would have attempted to mill it out and most likely milled through the casing. DarkVision has been called in by multiple operators for the same scenario after they have milled through the casing and lost the milling BHA in the open hole.

A clear understanding of downhole conditions prevented the operator spending significant time and money on interventions and jeopardizing their well. Instead, the operator was able to plan an effective and economical solution to getting the well on production.