Downhole Imaging

We’re setting a new standard for the inspection of casing, tubing, wellheads, and downhole components. We find, quantify, and render never-before-seen defects.

High-resolution Acoustic Downhole Evaluation System

Field Proven

DarkVision’s HADES™ is recognized as the most technologically advanced inspection platform across the industry. Our technology is being used in every major conventional and unconventional North American basin.

- 500000+

- Perforations Imaged

- 10793+

- Terabytes of High-Resolution Spatial Data

- 2036849537+

- Acoustic Images Captured

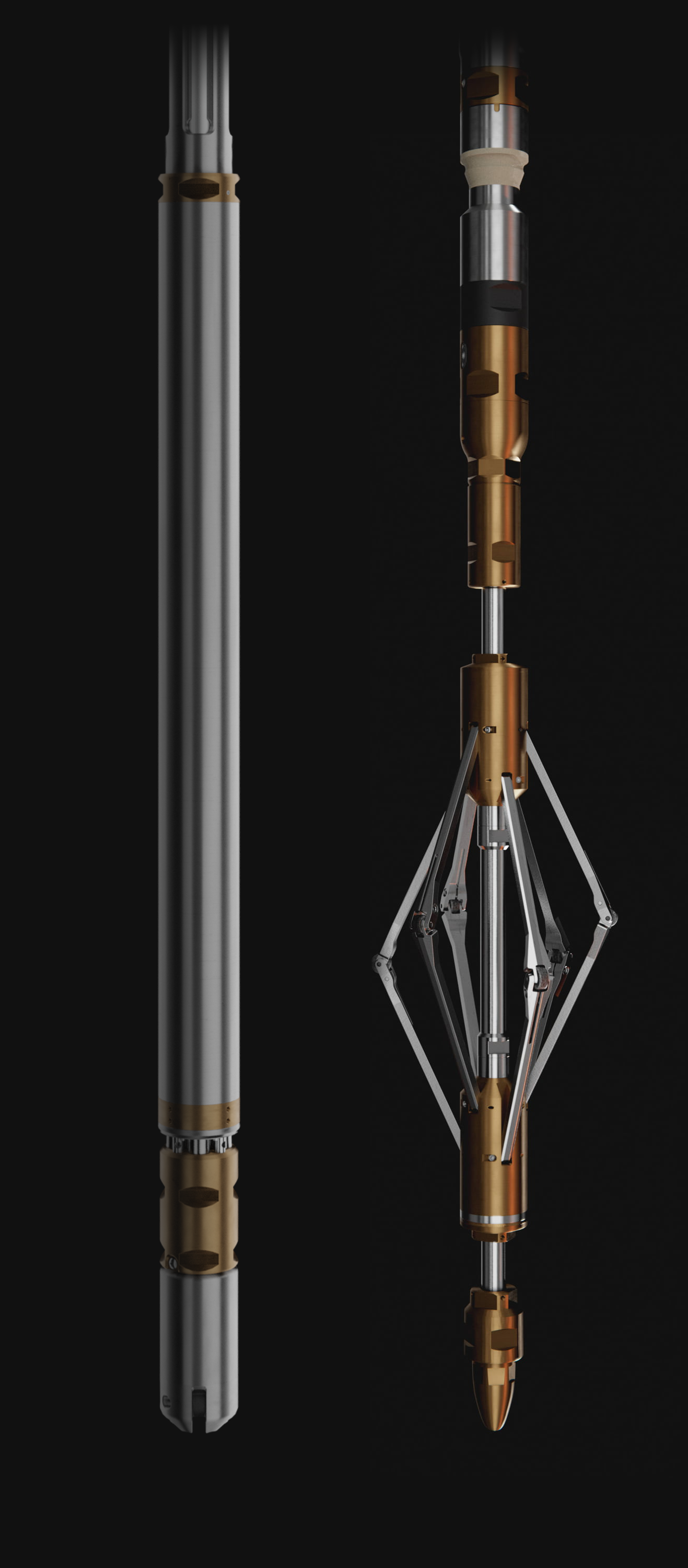

The HADES™ platform combines DarkVision’s unique high-resolution acoustic imaging technology with advanced robotics to deliver unparalleled downhole imaging capabilities.

Accurate 3D Measurements. Precise Results.

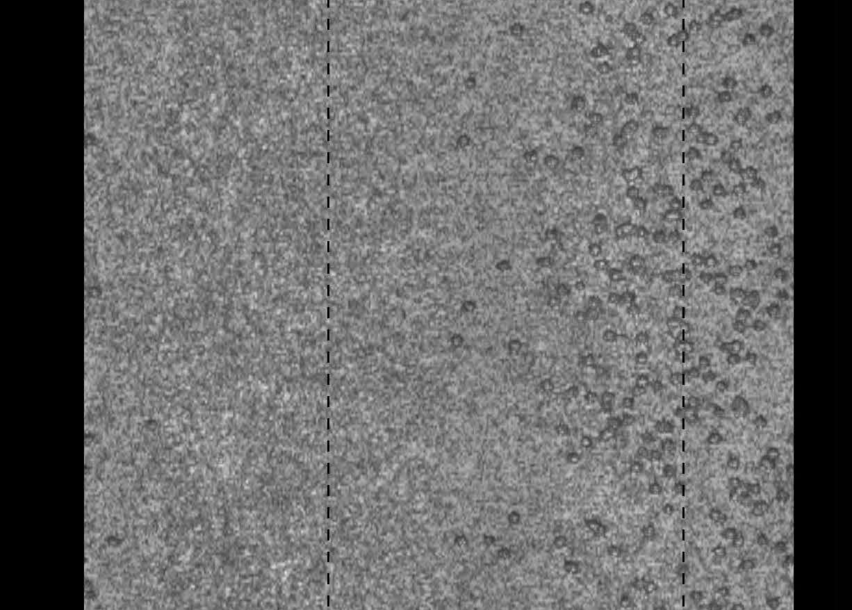

0.01” Resolution

Our tools deliver higher resolution so you can clearly identify issues and determine the root causes of failure.

Up to 512 individual transducers

We capture full circumferential scans using proprietary imaging modes only enabled by high-density arrays.

High-fidelity 3D visualizations

Say goodbye to subjective interpretations. Our system gives unmatched clarity with high-fidelity, intuitive 3D visualizations.

Field-proven and trusted

Our award-winning technology has been proven in the field by over 160 operators across all N.A. conventional and unconventional basins.

Direct measurements

We directly capture dimensionally accurate 3D data, removing the requirement for subjective interpretations.

Fluid agnostic

Our acoustic imaging system is fluid agnostic, enabling it to scan through water, brine, drilling mud, and production fluids. No more data loss due to cloudy or unclear fluids.

Field-proven and trusted by 180+ operators

Well Integrity Evaluation

Ensure safe well operation, improve burst pressure accuracy, and determine failure root causes with unprecedented levels of thickness and deformation data. We deliver complete circumferential imaging of tubing, casing, and connections to eliminate blind spots of legacy technologies like calipers and cameras.

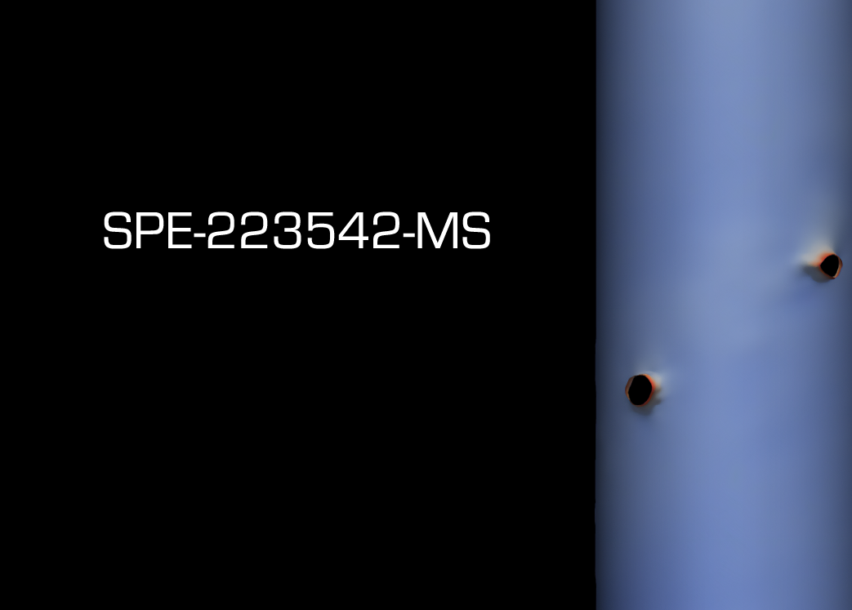

Perforation Erosion Analysis

Maximize production rates, improve operational efficiency, and identify plug damage with the most comprehensive perforation erosion analysis offering available on the market. We capture dimensionally accurate 3D measurements of each perforation and provide you with machine-learning-powered growth analytics. Oh, and you don’t need to swap fluid.

Obstructions and Restrictions

Gain unrivaled downward-facing 3D images of obstructions and restrictions in real-time to minimize unscheduled downtime. We remove ambiguity by providing a digital twin of whatever is impeding your well. And we do so all in real-time at the wellhead.

Complex Component Inspection

Acquire unprecedented submillimetric data to help you diagnose complex surface and downhole component failures. Whether it’s a wellhead, subsurface safety valve, liner hanger, or ICD – we will find damage, deformation, ovality, and leak paths like no one else.

Awards

DarkVision’s team, technology, and technical papers have won numerous industry awards.

2023

ICoTA Intervention Technology Award

USA

2022

GES Disruptive Digital Innovator Award

Canada

2022

ASME Best Mechanical Engineering Award

USA

2021

ICoTA Curtis Blount Outstanding Paper Award

USA

2020

OTC Spotlight on Technology Award

USA

2020

Hart Energy Innovator of the Year Award

USA

2019

ICoTA Innovation Award

Canada

Case Studies & White Papers

See More

Learn more about our technology

It all starts with better quality data. We’ve made fundamental advancements so we can deliver higher resolution data, greater coverage, and intuitive results.

Learn more