Unlock content

Share this

HADES-R + F

An operator in the Eagle Ford lost two BHAs in a well during mill out and after multiple attempts, they were unable to fish out the second BHA. The operator suspected a breach; however, they didn’t see evidence that they had milled out of the casing. Rather than continuing to fish blind, they decided to get clarity on what was impeding them.

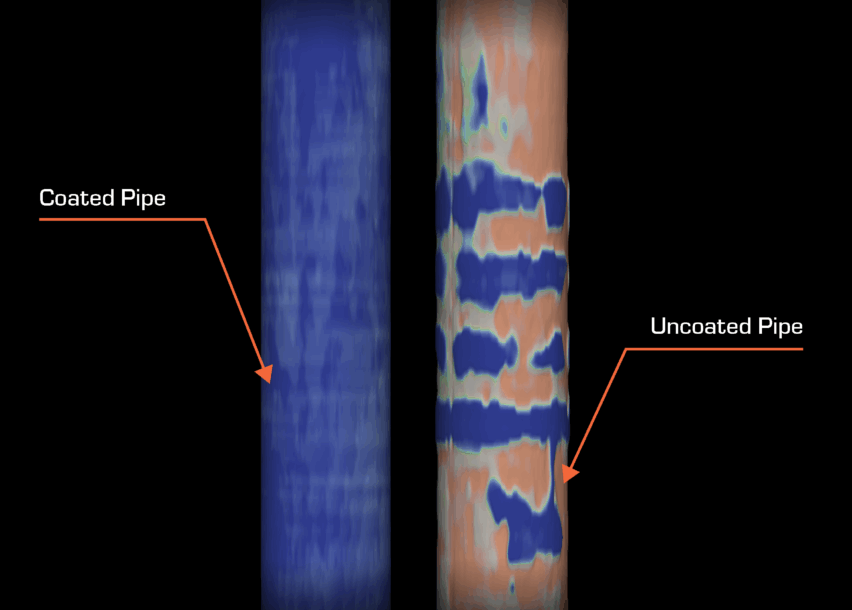

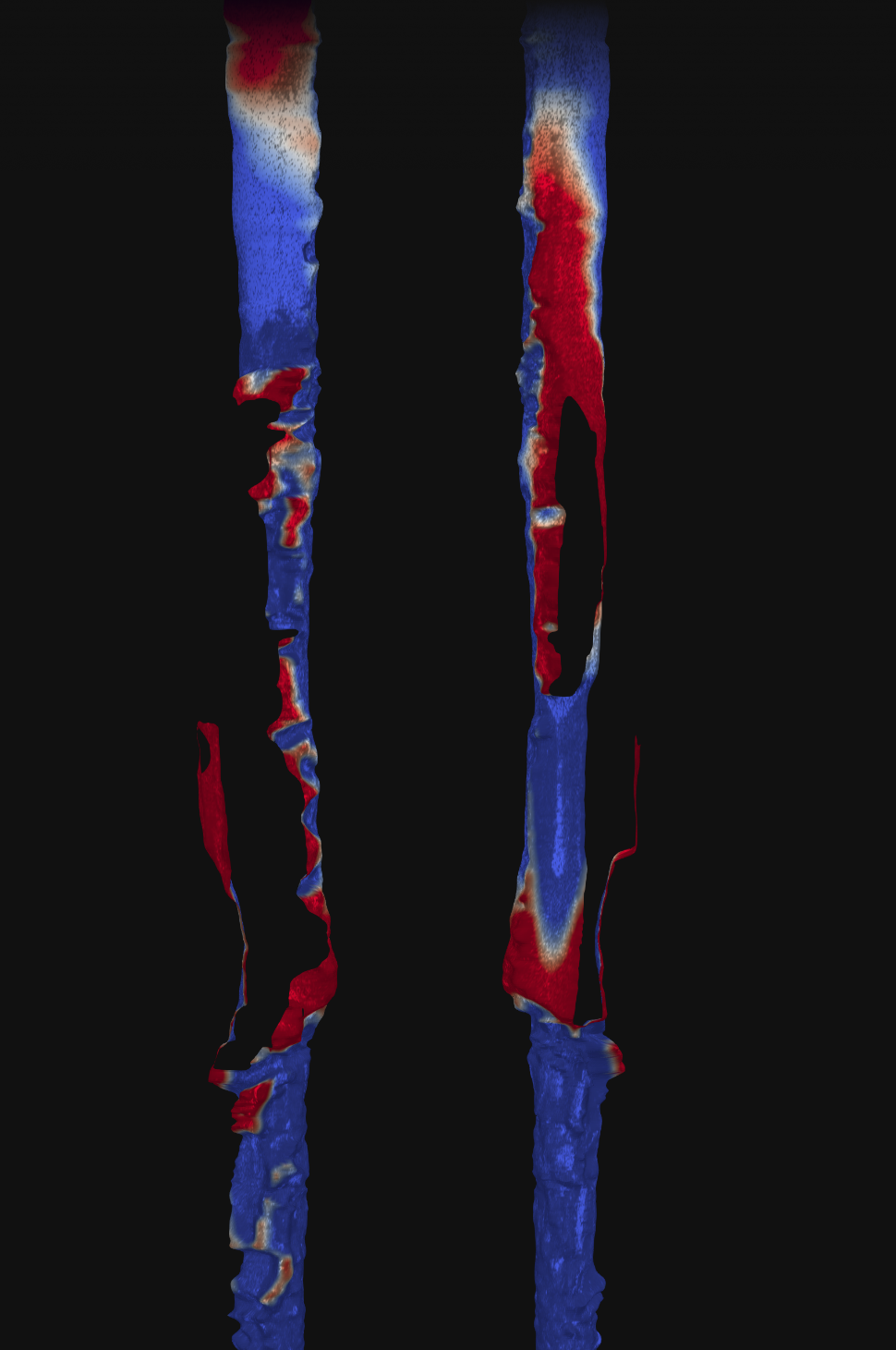

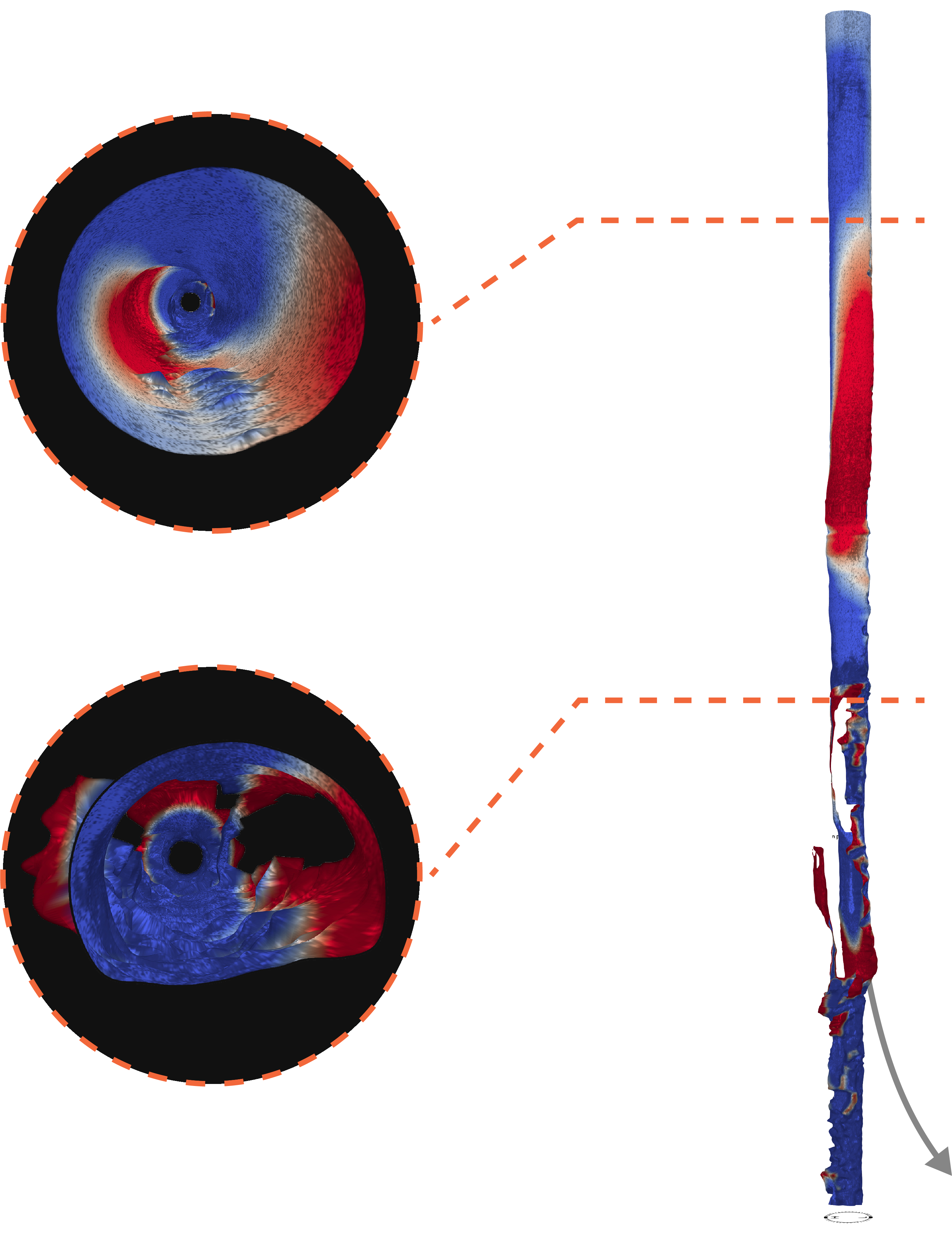

DarkVision was mobilized and identified a significant casing breach. Acoustic imaging results clearly showed that the tool strings sent down were not following the trajectory of the pipe but were exiting the casing through an unexpected breach into a ghost hole. Further imaging revealed the transition from casing to open hole as it went through the breach and even showed the backside of the casing as it deviated away.

This suggested that the BHA had also traveled through the ghost hole and was unlikely to be recovered. Armed with this information, the operator was able to prevent further time and effort being spent on fishing operations.

The operator noted that they had not been able to reach the intended plug set depth. Further analysis revealed an area of high ovality immediately above the plug. It was suspected that the plug did not seal over this high ovality section, enabling abrasive frac fluid to create an erosional channel which severely abraded the casing wall and resulted in the breach.

By clicking Submit you’re confirming that you agree and consent to our Terms and Conditions.