Unlock content

We set a new standard for industrial imaging. DarkVision delivers the highest resolution, the highest defect detection rate, and the most intuitive defect visualizations in the harshest environments known to man.

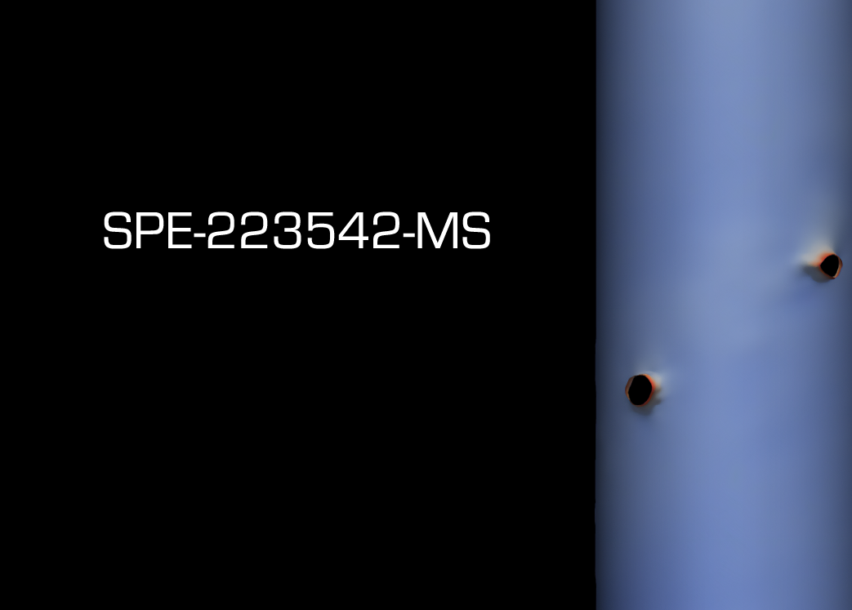

Kraken’s advanced direct imaging technology empowers pipeline operators to fully understand the shape, size and morphology of anomalies and their root cause before digging.

See full application

Our HADES™ platform collects high-fidelity 3D point-clouds of data with every run – delivering up to 30,000 ft of data without the need for clear fluids.

See full application

Critical assets like water mains and petrochemical pipelines are the life support systems of modern society.

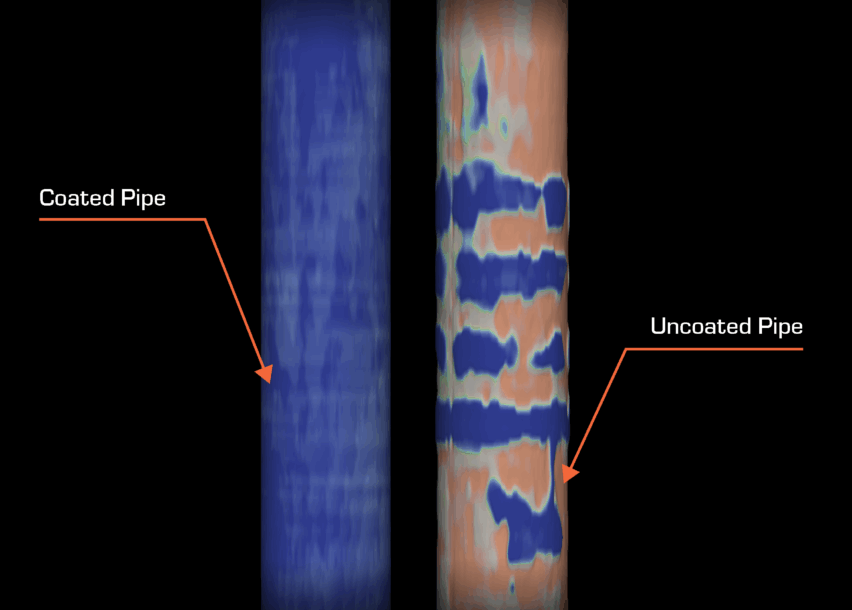

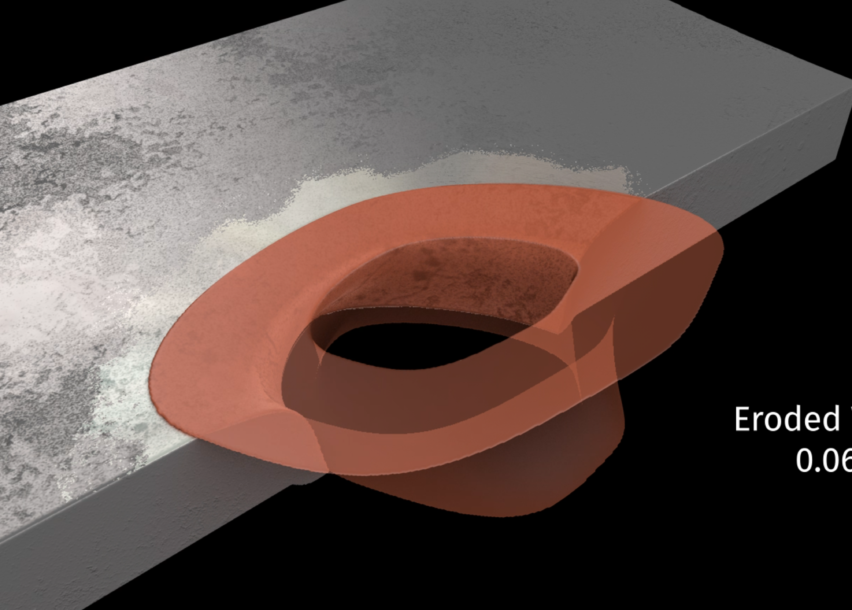

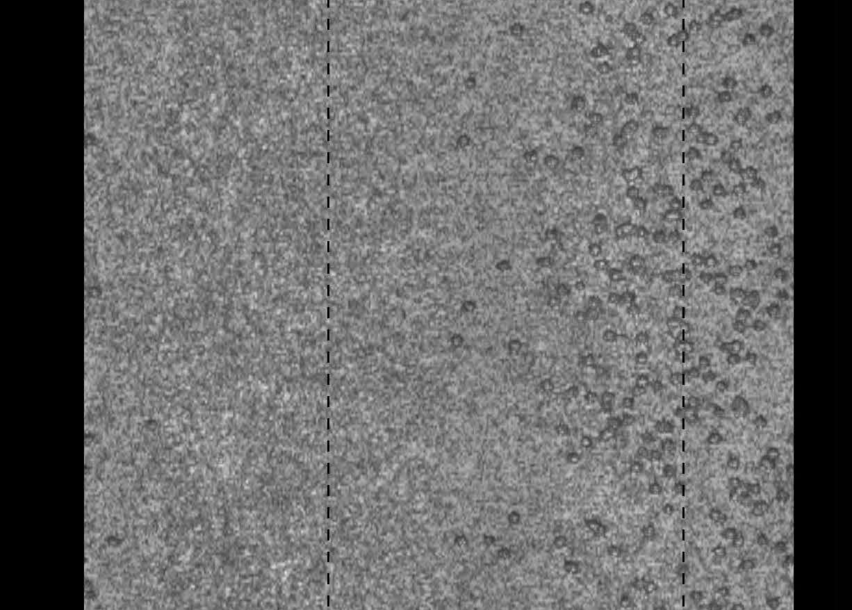

The integrity of these assets is paramount; dents, axial cracks, circumferential cracks, and corrosion threats need to be found, quantified, and repaired to keep people moving forward. DarkVision’s high-resolution acoustic imaging technology provides spatially registered, submillimetric measurements of all defects in a single pass.

We ensure that assets go above and beyond regulatory requirements through high-fidelity detection, sizing, and visualizations of defects.

Our assets are aging, and regulatory standards are increasing to a level like never before. Cracks, corrosion, and inclusions in infrastructure from pressure vessels to storage tanks need to be identified and quantified with precision to reliably predict and prevent failures. DarkVision’s high-resolution acoustic imaging technology provides spatially registered, submillimetric measurements of critical defects that the industry has never seen before. Oh, and we do it faster and in a smaller package, just because we can.

Regardless if it’s wind, nuclear, natural gas, or solar, the structures and equipment supporting today’s energy needs are under immense stress.

Defects must be found, sized, and understood with speed and accuracy, whether inclusions in composite wind turbines or stress corrosion cracking in nuclear flow lines. Manually interpreted datasets are a thing of the past. DarkVision’s high-density arrays and proprietary imaging modes, paired with unprecedented data processing and visualization techniques, overcomes limitations fundamental to low-resolution, low-fidelity datasets from legacy equipment.

Chances are the majority of the things you use daily, travel in, or rely upon are not manufactured in your country.

Reliability, sustainability, and longevity of equipment transporting daily-use items are critical. Cracks in rail wheels, corrosion on marine vessels, or inclusions in the carbon fiber unibody in your new car are disruptive and expensive to everyone in the supply chain. New ultrasound inspection techniques, only viable with the latest chipsets and arrays, keep things moving.

Base-metal pipes, bars, and plates are the literal building blocks that just about everything we rely upon in modern life is made of.

Raw metal or composite materials require an inspection before forming products for use. We’re advancing the capabilities to find, assess, and visualize these flaws. Insanely fast inspection speeds, single-pass full-coverage, resolutions of 0.01”, and photorealistic 3D visualizations are vital parts of unlocking operational superiority, reliability, and profitability.

Call us ambitious or relentless optimists, we debuted our advanced acoustic imaging technology in one of the harshest arenas known to man.

DarkVision’s HADES™ platform provides defect detection at over 150°C and 15,000PSI. It provides holistic integrity data for tubing and casing at resolutions exceeding 0.01” (or 0.25mm for us Canadians). It wasn’t easy, but our first product line has been immensely successful, with field-proven results from over 1000 field runs and 1B+ images. Downhole Imaging Details

Our proprietary solid-state high-resolution acoustic imaging technology sets a new standard for industrial asset inspection. DarkVision’s tools deliver higher resolution data, greater coverage, and intuitive results.

Discover our technologyUnlock content

Unlock content

Unlock content

Unlock content