Application

An operator was hydraulically fracturing a well when they encountered an obstruction in the vertical near the liner hanger. They called in DarkVision to deploy HADES-F and R in combination to identify the cause of the obstruction.

Objectives Achieved

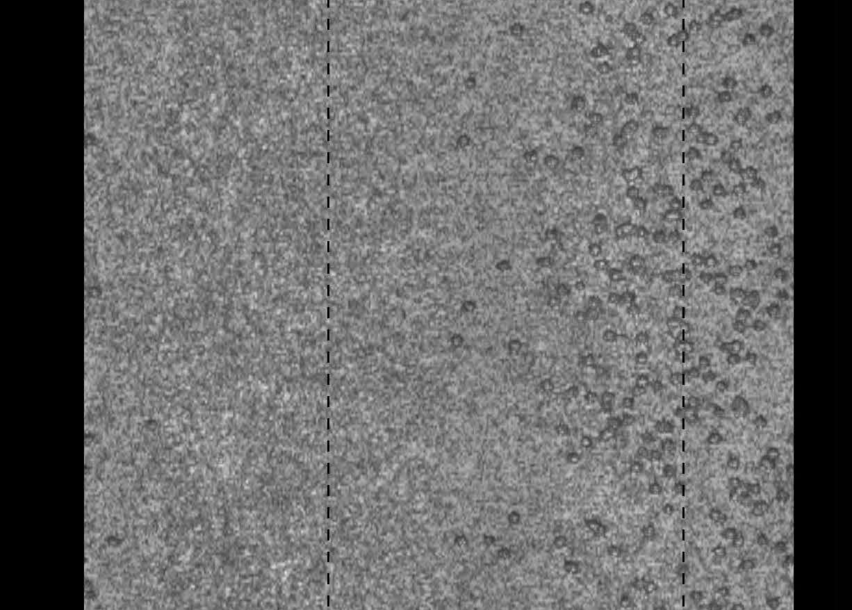

First, the obstruction was scanned with HADES-F, DarkVision’s downhole facing tool. The report indicated that the obstruction was soft sand, with the exact dimensions of a slim-hole weight bar used in a prior wireline intervention run indented into the top.

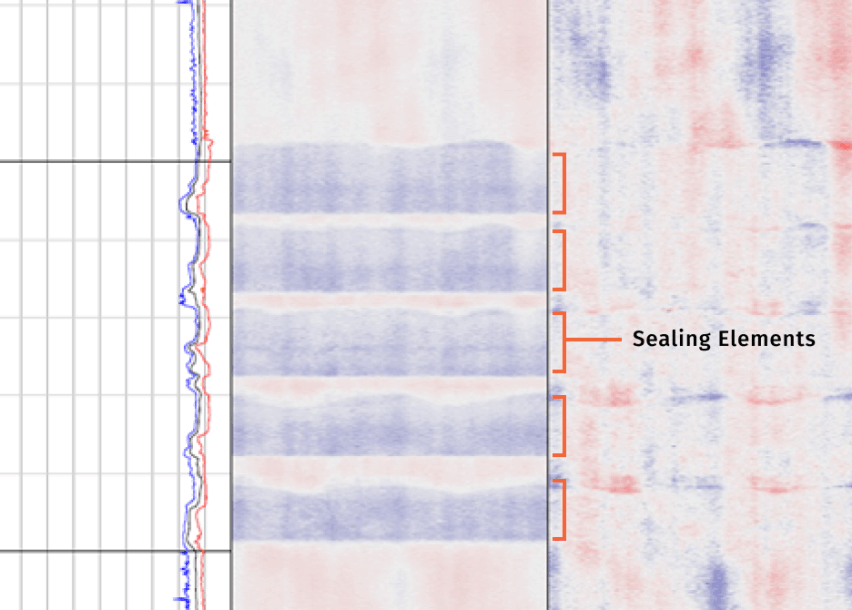

Above the obstruction, HADES-R found damage and an axial split on the polished bore receptacle (PBR). The operator suspected that damage had limited circulation between frac stages and the sand had accumulated to form the obstruction.

Results

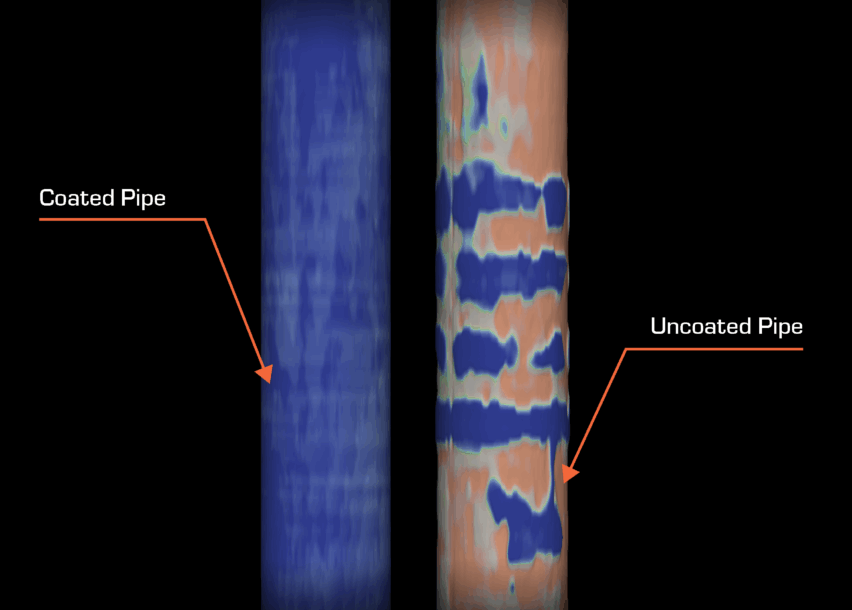

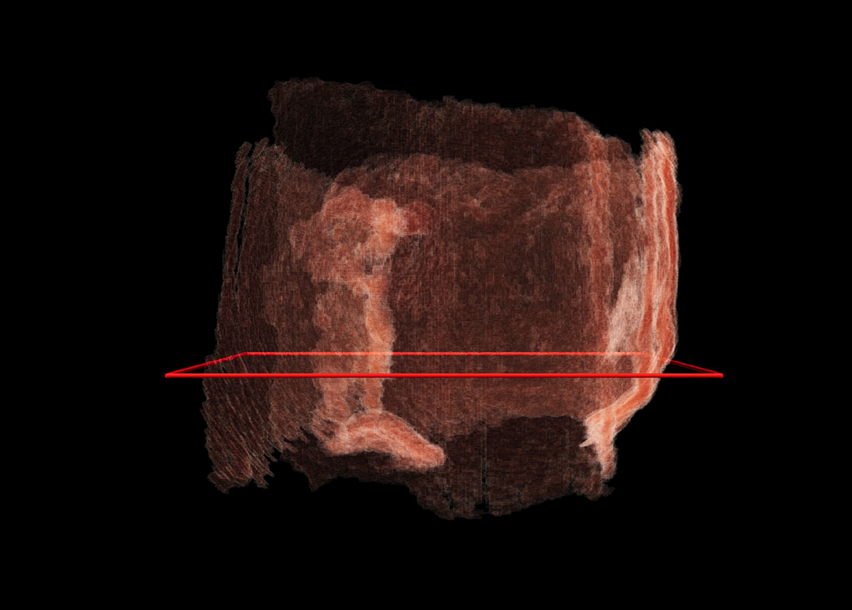

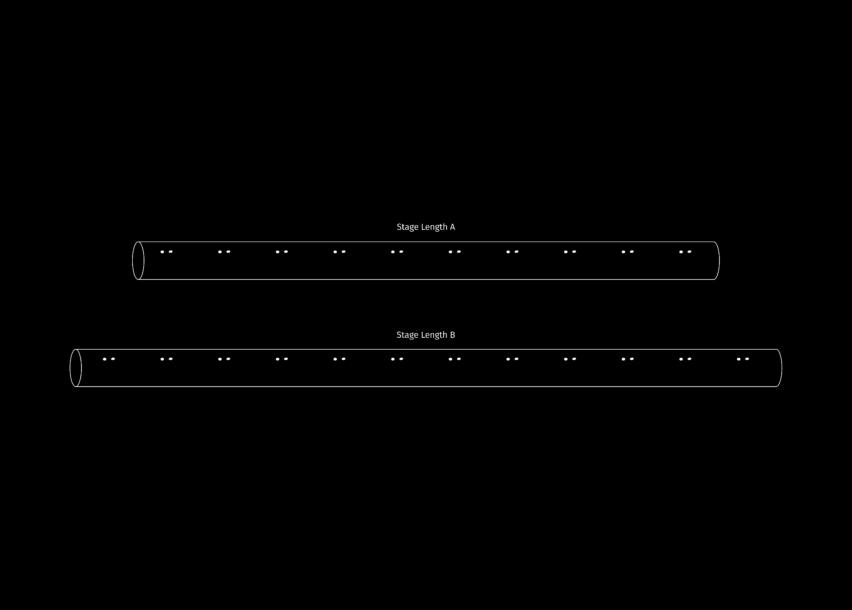

Based on the DarkVision report, the operator had a clear action plan to circulate and clear the debris and finish the well completion. To understand the frequency of occurrence, the operator asked DarkVision to perform a well integrity analysis of the crossover and PBR of a subsequent well on the same pad during a scheduled perforation erosion analysis.

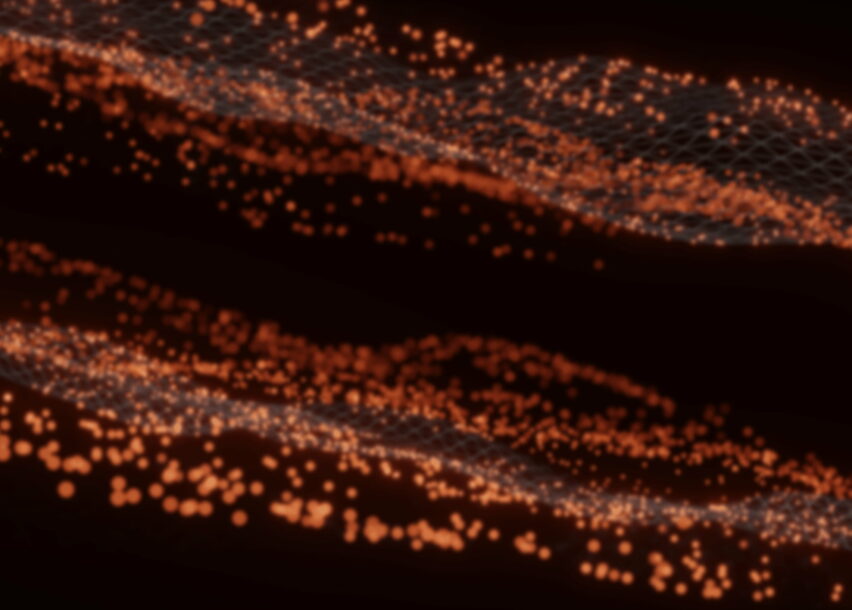

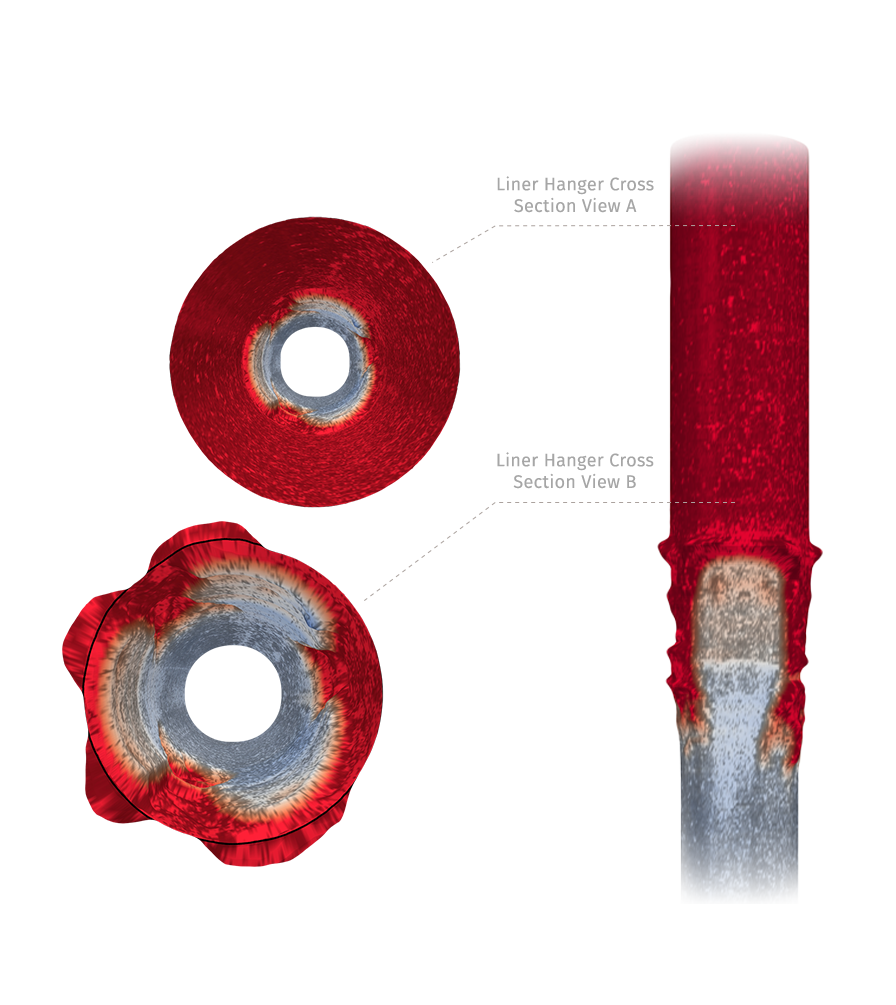

The well integrity analysis demonstrated the same damage profile with an axial split on the PBR of the second well. The liner hanger assembly was also observed to be significantly damaged. On the initial well, the liner hanger depth was below the obstruction and therefore not imaged. Significant damage to the liner hanger would explain a zone of low fluid flow above the liner and accumulation of sand in that zone to form the obstruction.

The repeated damage profile of the liner hanger assembly in two wells on the pad led the operator to suspect that this damage could be happening frequently, putting their wells at risk. DarkVision has found an increased frequency in liner hanger damage as operators are increasing the size and rate of their frac. Lost production from the abandoned and unstimulated stages on the initial well exceeded $10 Million. With this insight, the operator modified their future casing design from a liner to a full long string to surface, eliminating the operational and financial risk on future wells.