Technology Used

HADES-R and T

Well Information

- Well Type

- Gas Storage

- Application

- Well Integrity Evaluation

Application

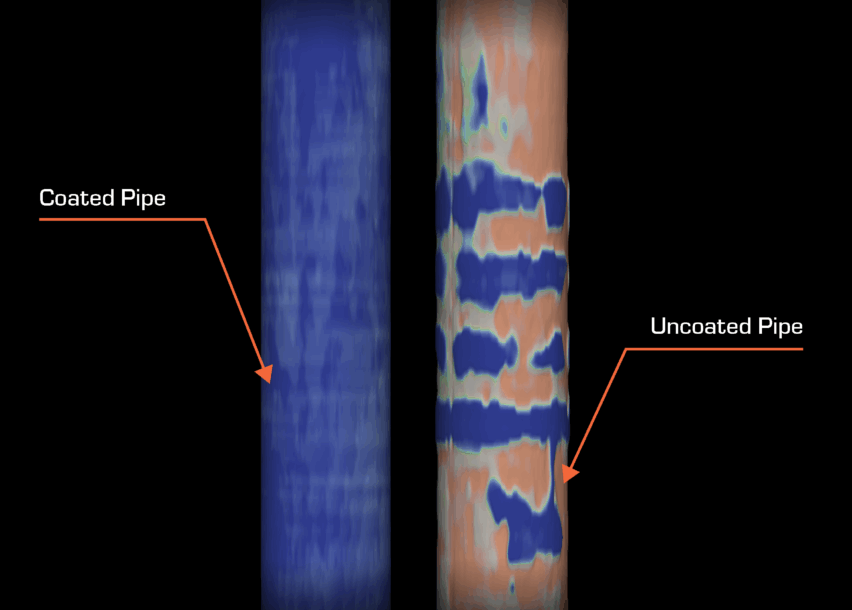

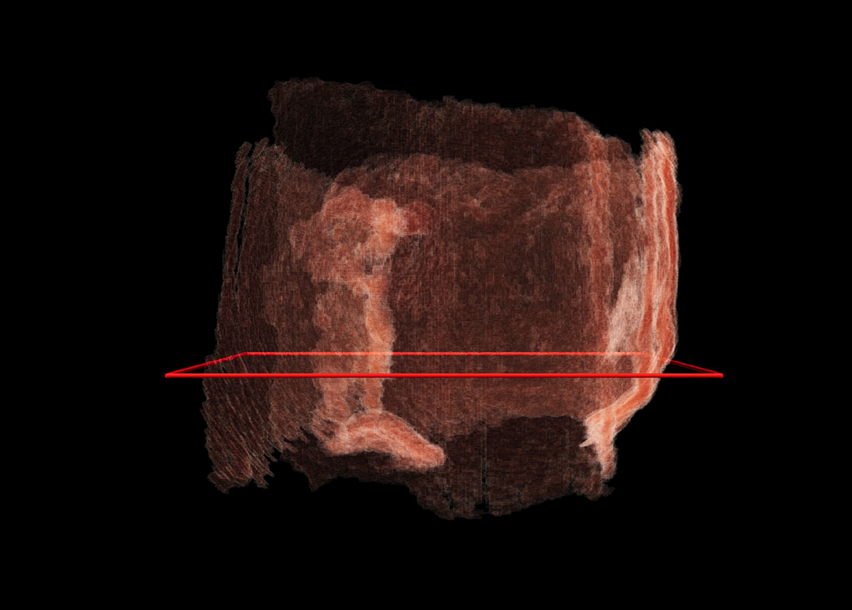

During a routine inspection, an MFL tool reported a limiting defect of 80% wall loss. Since wall loss to this extent would require an expensive workover and significant downtime, the operator contacted DarkVision to validate these measurements and determine if the workover was necessary.

Results

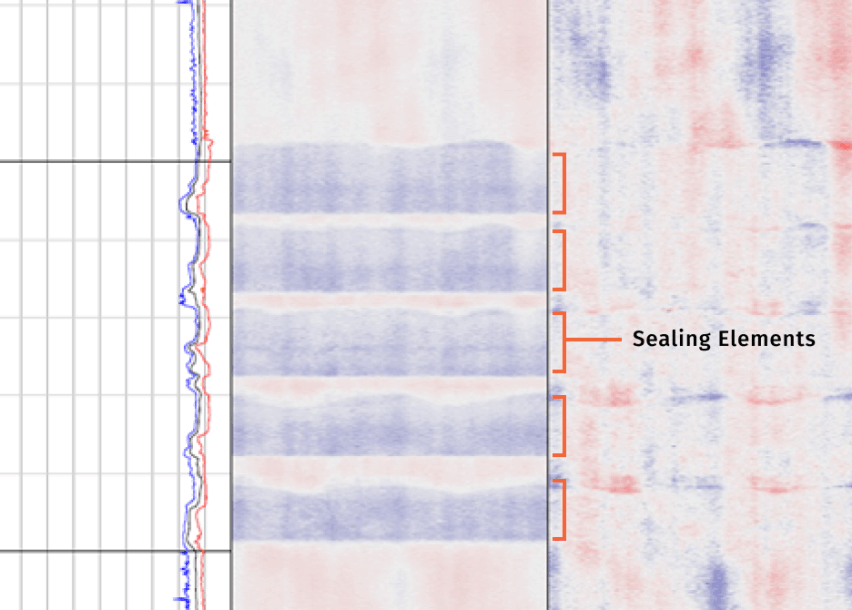

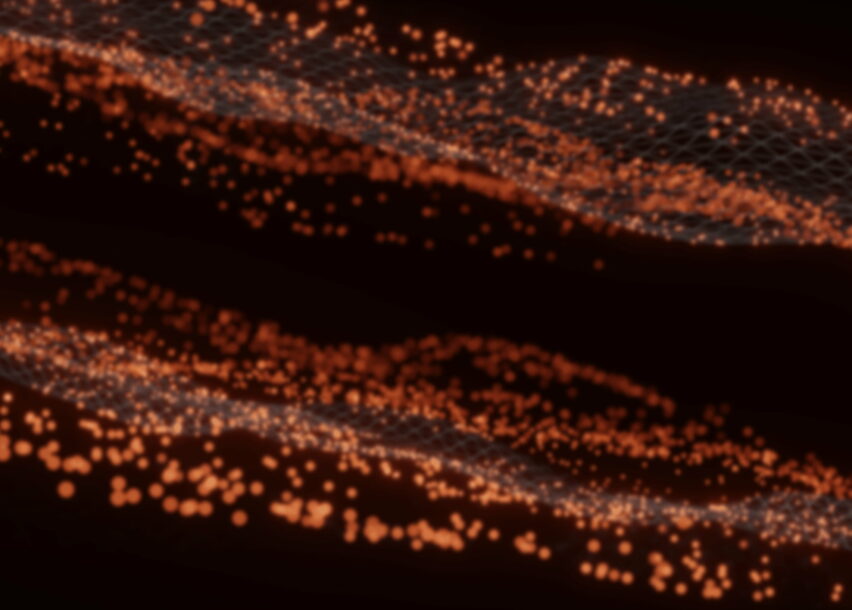

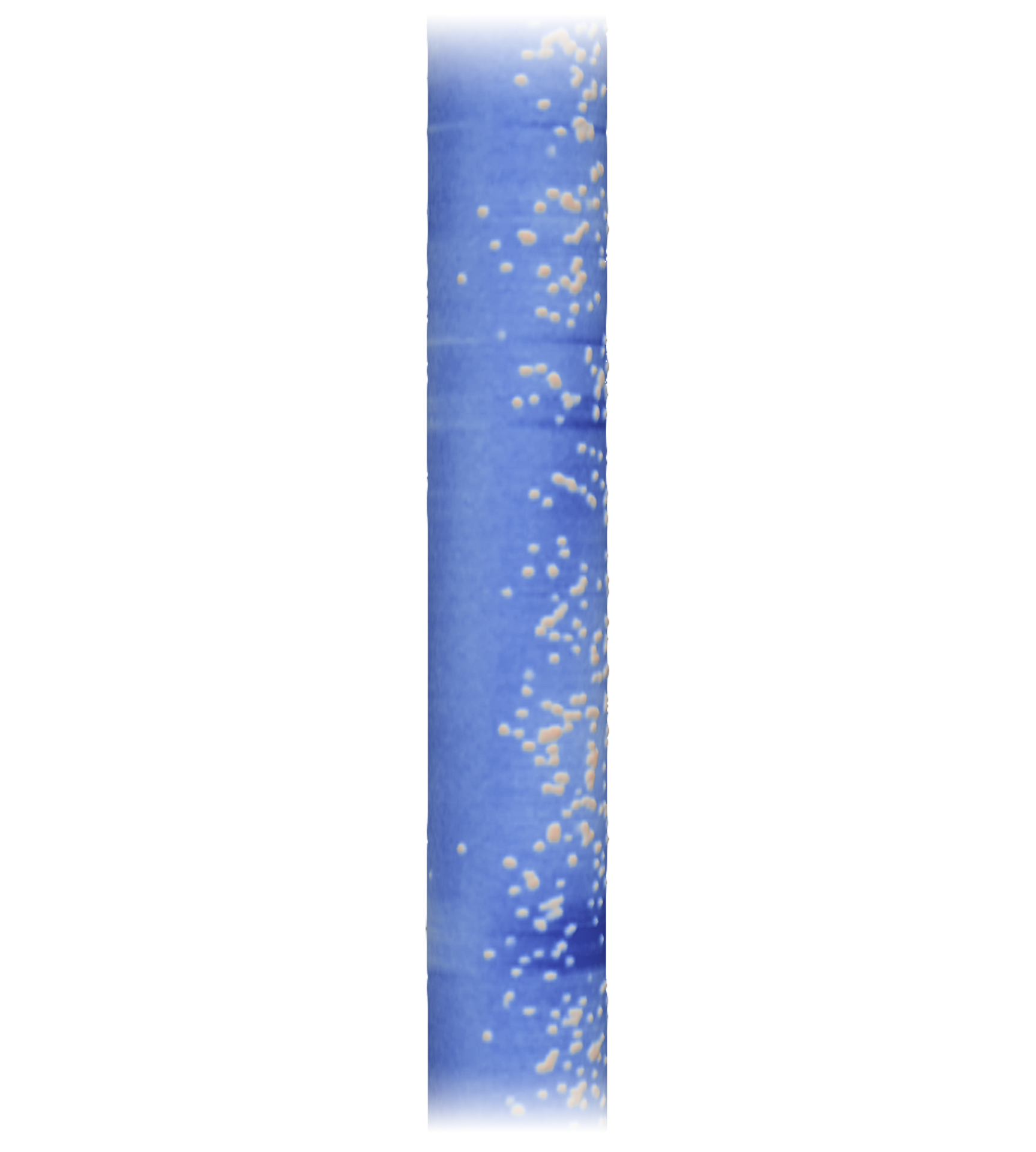

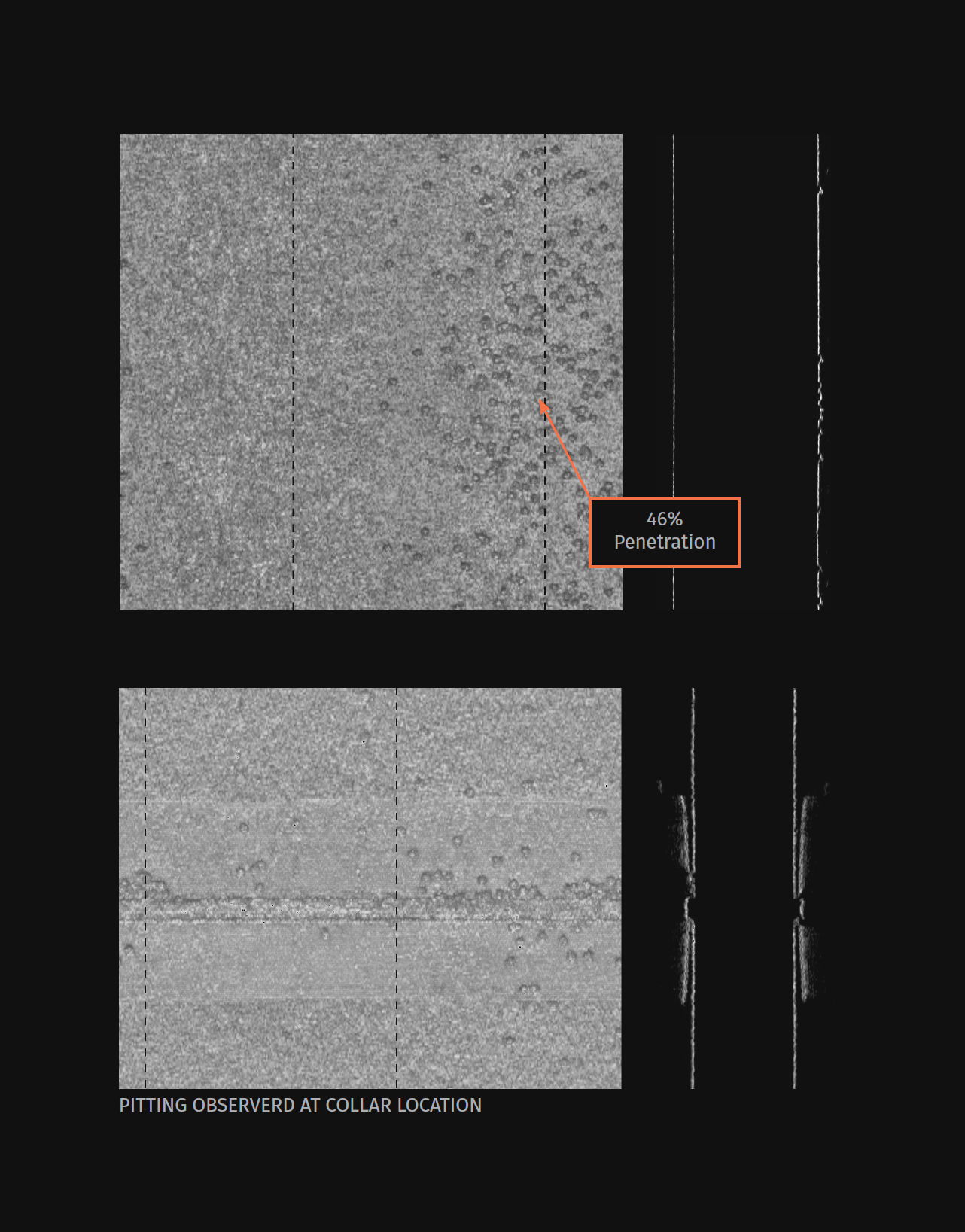

DarkVision’s scan provided unprecedented characterization of pitting in this gas storage well. The operator was able to understand the root cause of the wall loss through the visuals provided. Even pitting within the collar was characterized, an area where other technologies would fall short due to the changing geometry. DarkVision determined that wall loss on the casing ID had a maximum penetration of 46%, which resulted in a burst pressure that fell within their safe operating range unlike the result from the MFL.

Outcome

Based on DarkVision’s well integrity and burst pressure report, the operator determined that the workover was unnecessary, saving an estimated $400K in direct costs and avoiding significant downtime. The direct measurements and characterization of wall loss enabled the operator to confidently determine the root cause of the wall loss and plan mitigation to address it. This also provided the operator with valuable insights for maintaining the integrity of other gas storage assets.