Technology Used

HADES-R and T

Well Information

- Well Type

- Unconventional

- Application

- Investigate Cause of Breaches

Application

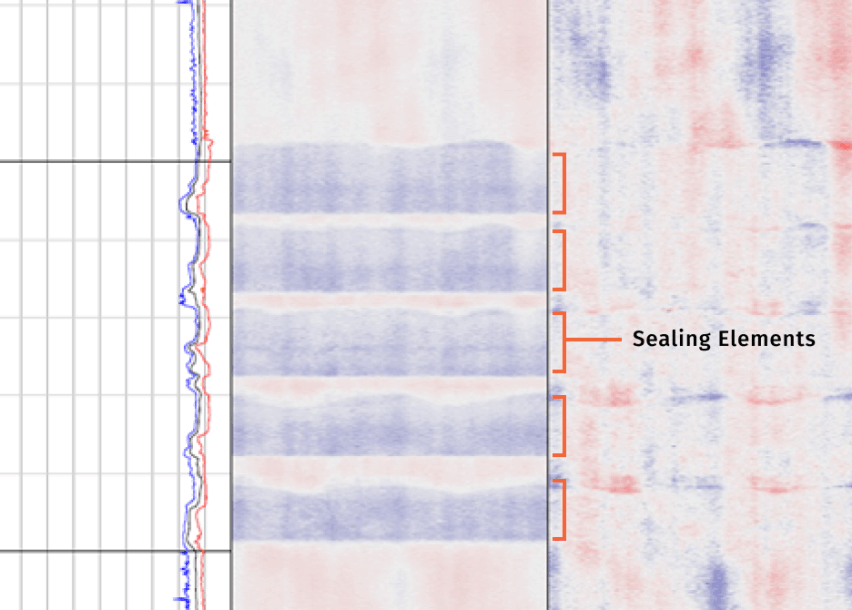

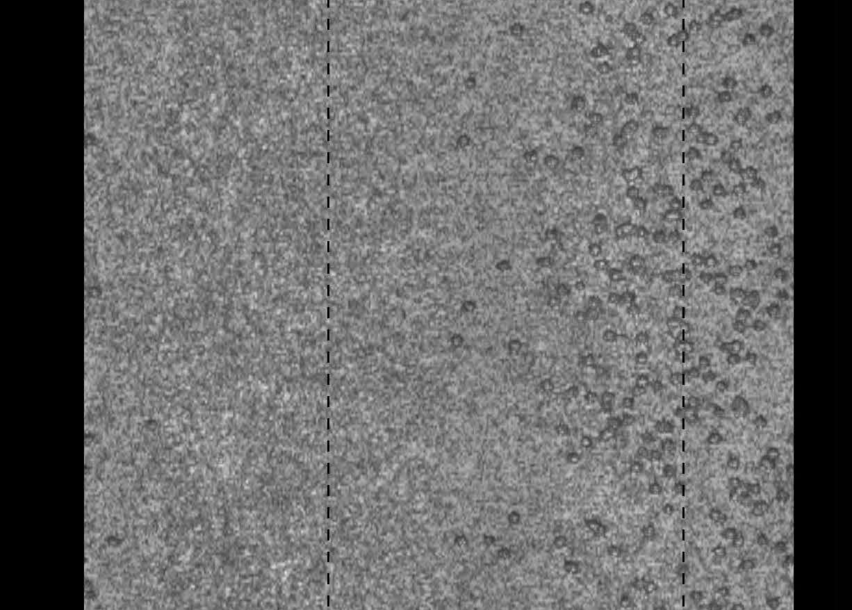

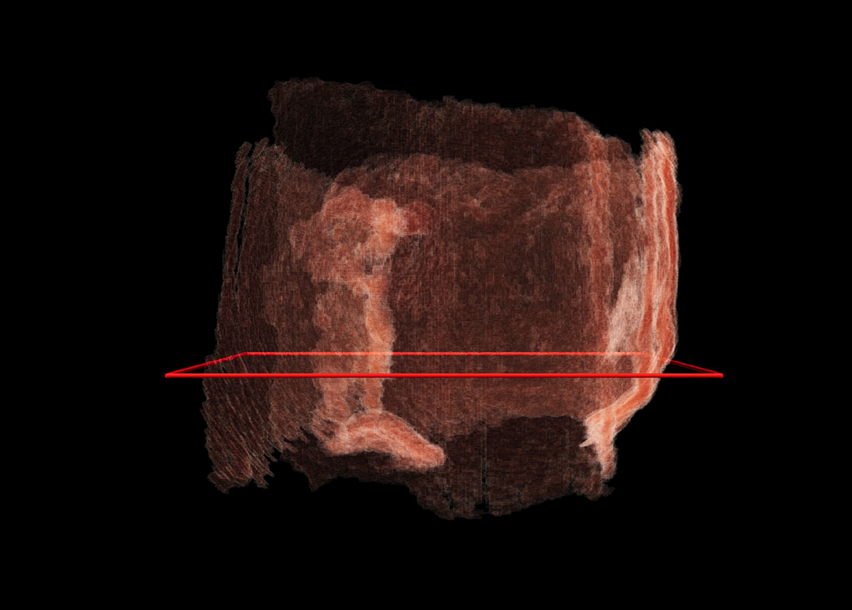

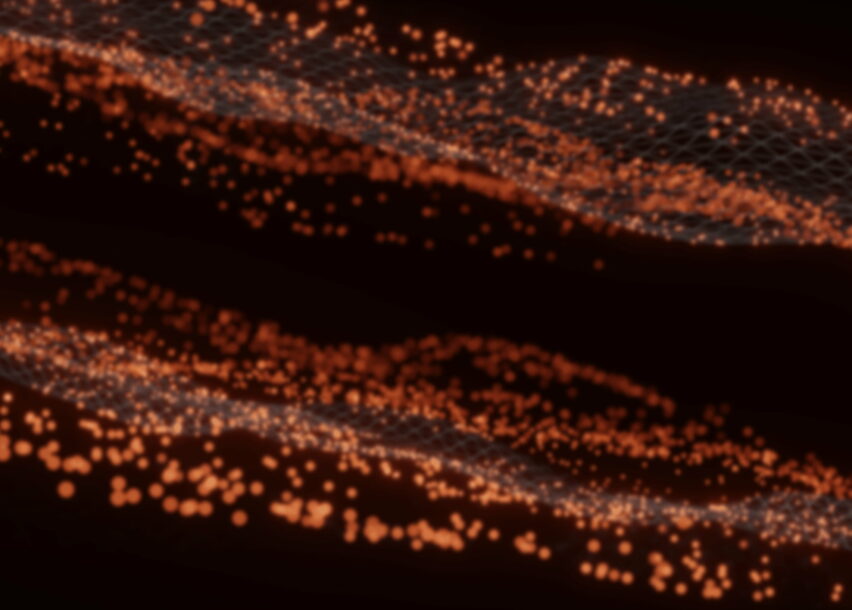

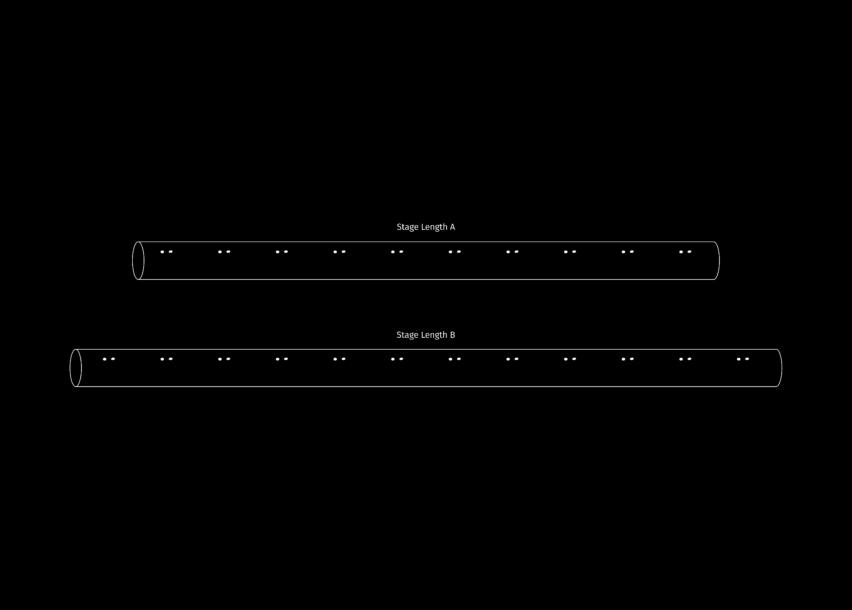

An operator had breaches during the initial stages of fracking for several new wells in the same region, resulting in significant downtime and costs for remediation. DarkVision was called in to understand what was happening and deployed HADES R and T tools in combination to directly measure ID, backside wall loss, and casing thickness with submillimetric precision.

Objectives Achieved

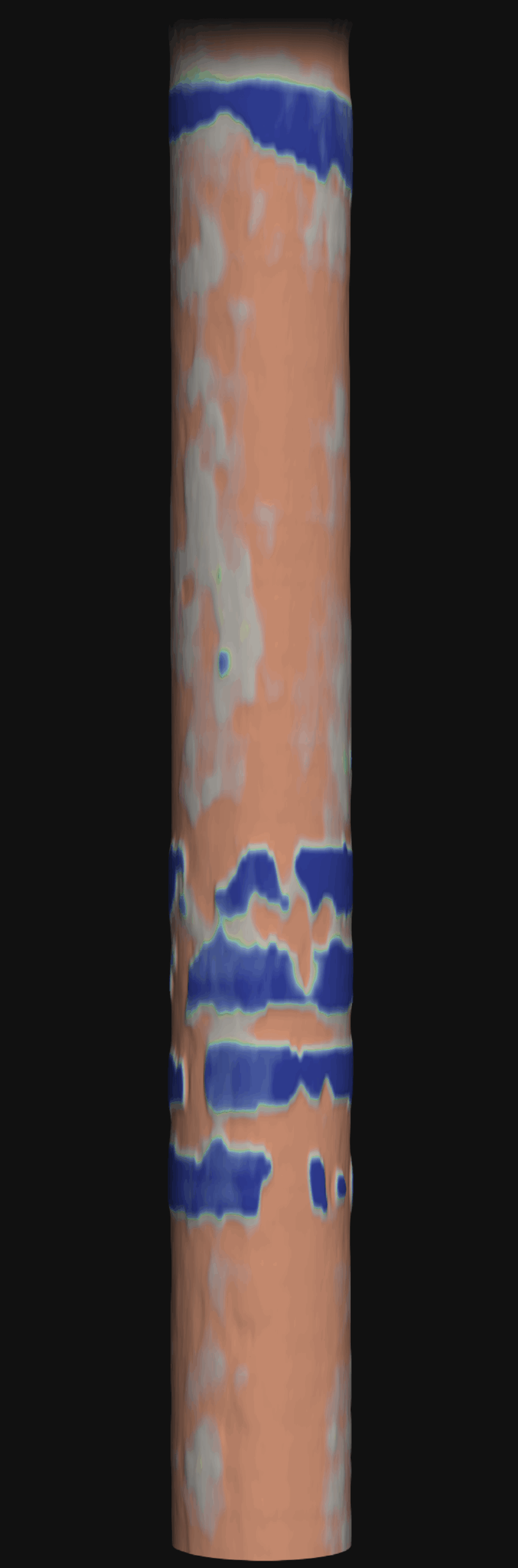

DarkVision performed a full well integrity analysis for a series of wells in the field. In each case, the inner diameter (ID) of the casing was in excellent condition, as expected for recently drilled wells. The outer diameter of the casing (OD) showed corrosion ranging from minor to extreme, with significant external corrosion in most wells. Based on this pattern, the operator was confident that field-based corrosion was the root cause of the casing breaches.

The newest of these wells had wall loss below the 12% threshold typically used for wall loss reporting. This casing was manufactured with a particularly tight tolerance considerably below 12%. Due to the accuracy and characterization of wall loss in DarkVision’s inspection, it was clear that this wall loss was due to early-stage corrosion and not manufacturing variability. By clearly differentiating between manufacturing variation and early-stage corrosion, the operator was able to understand and mitigate early-stage corrosion in this well.

The report provided by DarkVision also demonstrated a significant difference in performance between coated and uncoated casing used in a single well. In the joint where two different types of casing met, the uncoated casing had a higher degree of corrosion. This information helped the operator assess the performance of different components, and the efficacy and cost effectiveness of different corrosion mitigation methods.

Results

The operator was able to successfully hydraulically fracture the rest of the wells in the field without new breaches by staying below the burst pressure threshold provided in the well integrity report. They were also able to successfully remediate and complete the breached wells and bring them to full production.

The operator also gained valuable insight into preventing and addressing external corrosion in this region, enabling them to plan cost effective and reliable mitigation measures and avoid costly and disruptive breaches in the future.