Application

An operator completed a hydraulic fracture design optimization project in the Midland Basin to determine if they could switch to a lower cost design without sacrificing production.

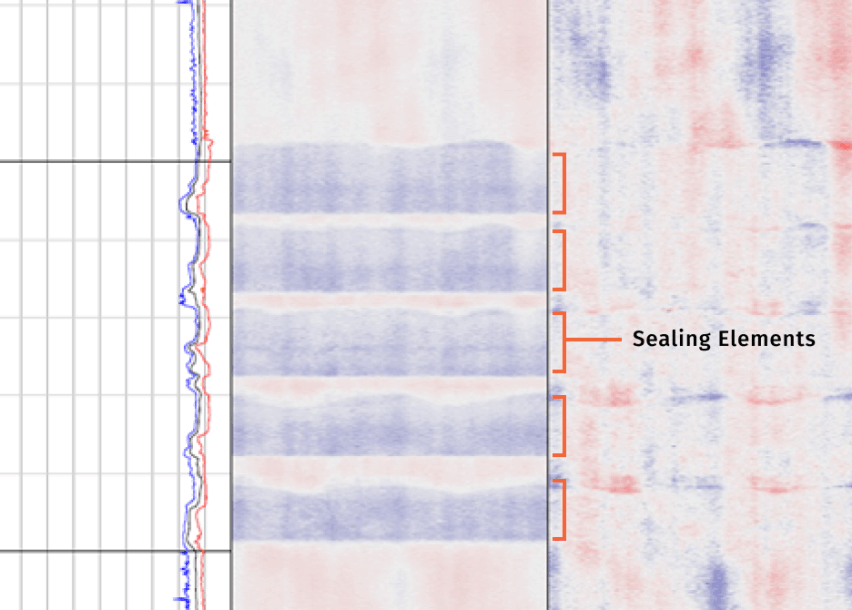

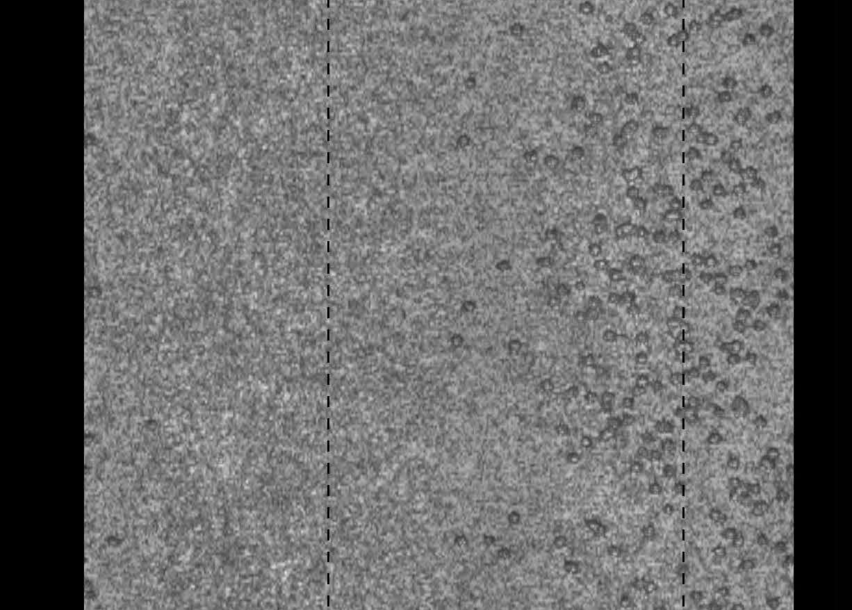

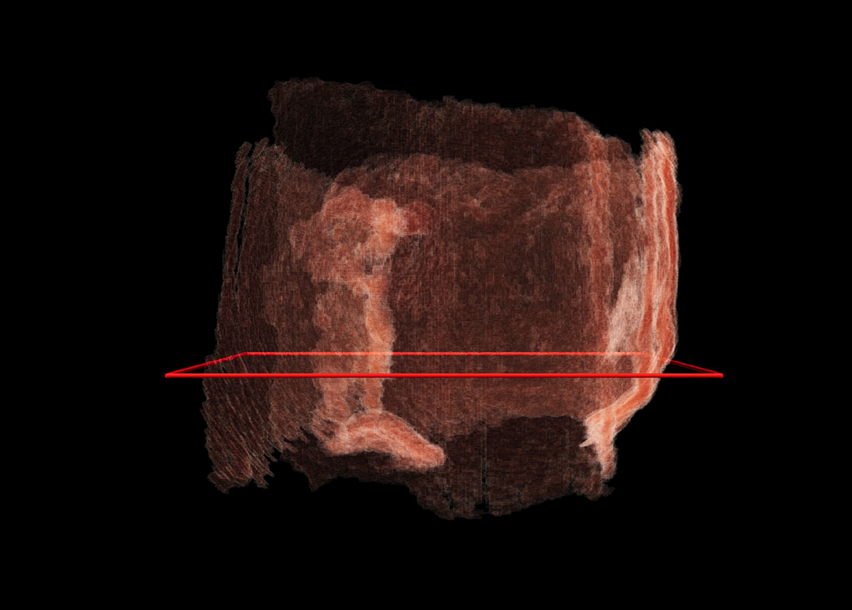

The new design extended the stage length, moving from 10 to 12 clusters at the same cluster spacing. Longer stages increase efficiency and reduce the time and cost to hydraulically fracture a well. The benefits of reducing completions costs applied over an annual drilling and completions program scale quickly, so long as those savings are not offset by lost production. This operator ran DarkVision to understand the potential impacts on well performance by assessing the perforation erosion and uniformity of the 12-cluster design.

Uniformity index is an industry accepted calculation used to evaluate how effectively a given stage has been fractured.

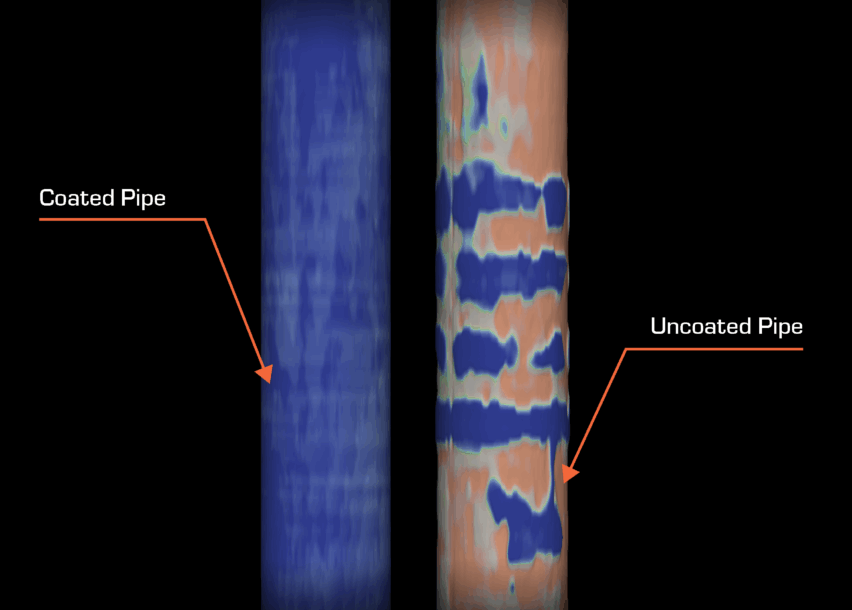

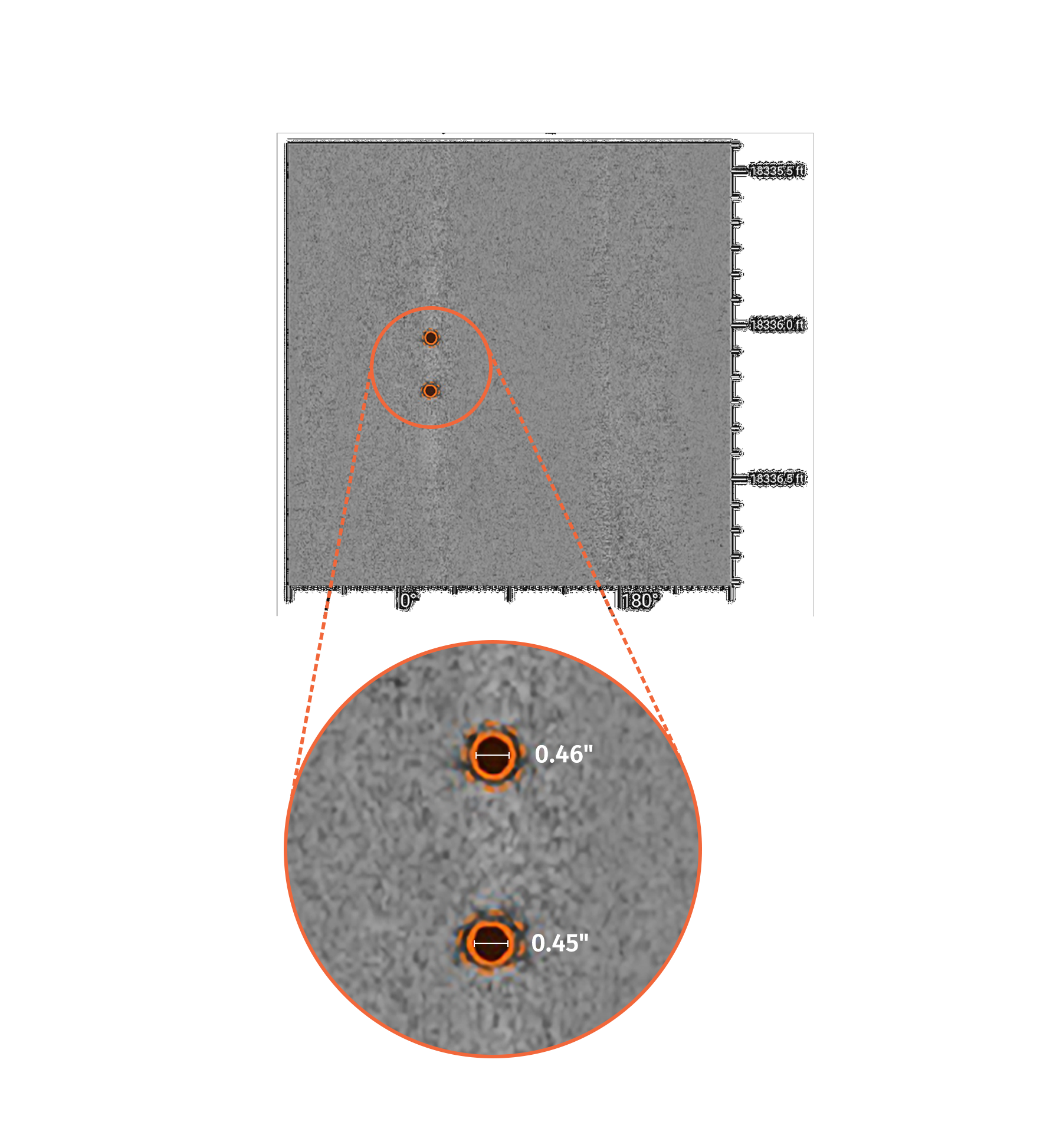

Increasing the cluster count per stage would necessitate a change in perforating gun design. Therefore, the operator also wanted to rank the performance of a variety of perforating gun and charge manufacturers to select top performing equipment and wireline vendors.

Objectives Achieved

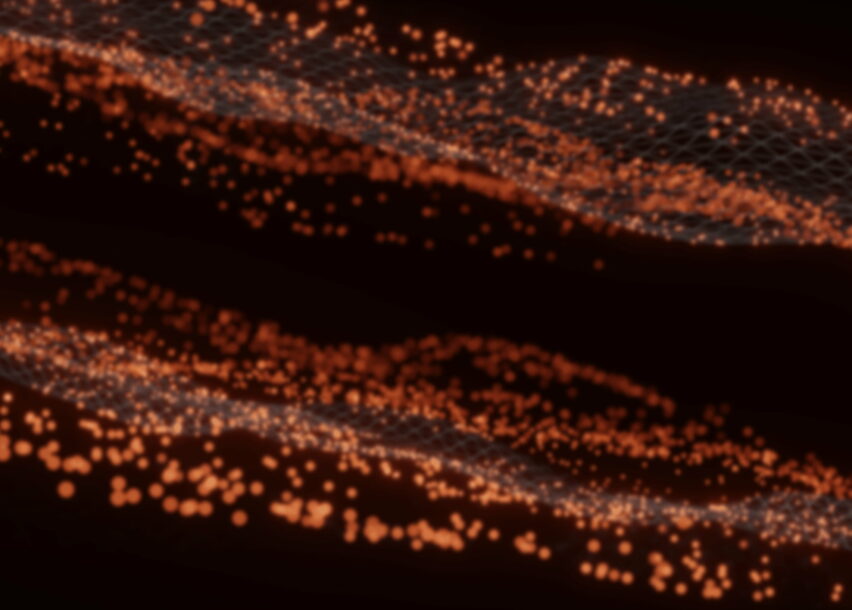

DarkVision performed a comprehensive perforation erosion analysis of forty stages in the subject well. The analysis assessed perforation erosion, uniformity index, gun orientation, and charge performance. The new 12-cluster design increased the uniformity index by 0.13 versus the legacy design, with higher perforation erosion and consistently even bias across the stage.

The operator was also able to identify a clear top performing self-oriented gun system and rank the downhole performance of seven different perforating charges. Large variability was observed in downhole reference hole diameter, with the coefficient of variance ranging from 0.03–0.11. This operator now has a playbook including a ranked hierarchy of charge, gun, and wireline vendor performance for their primary fracture designs.

Results

The operator confidently switched to the new design, achieving significant cost savings with an expected positive impact on well performance. Early production ranks this well in the top 15% of the operator’s wells in the vicinity.

Additionally, the operator calculated completions cost savings of $200,000 per well based solely on the increased efficiency and, when applied to their 30 well program, was evaluated at $6 Million in annual benefit.

The perforation erosion analysis also identified the top performing plugs, perforation guns, and charges for each design, providing the operator with a selection of consistently high performing components to ensure proper execution of their selected design.