Technology Used

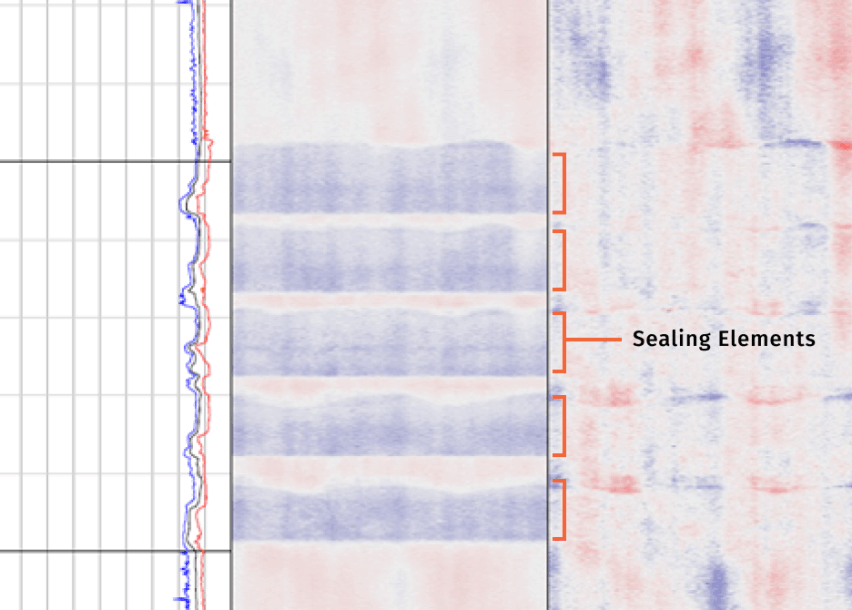

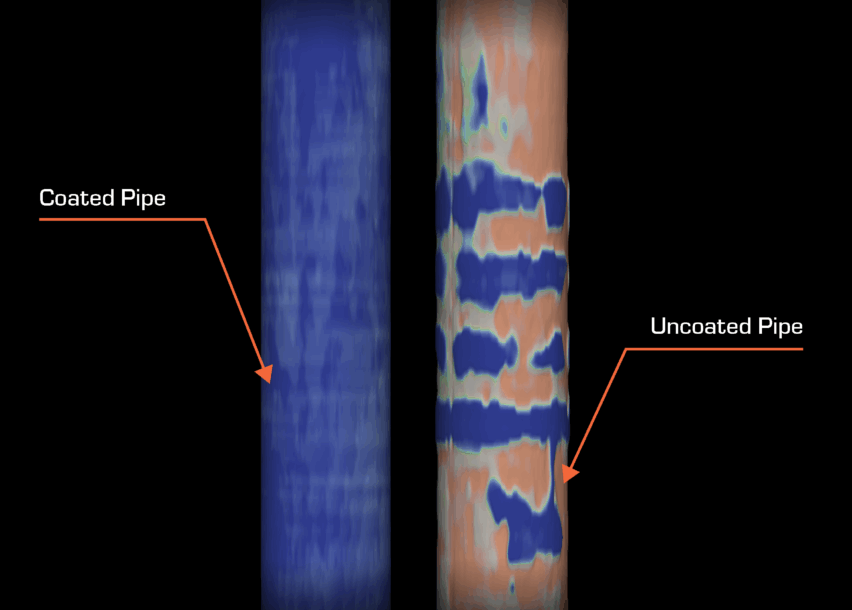

HADES-F

Well Information

- Location

- North Sea

- Operation

- Identify Obstruction

Application

A high temperature, high production offshore well suddenly stopped producing after an unplanned shut down. The operator attempted to determine the reason for the production loss, but the intervention tools hit a holdup depth (HUD) above the top perforations.

The operator first hypothesized that the obstruction could be sand and performed three intervention operations to remove it from the HUD without success. The suction tools returned an asphaltene-like substance and some debris – not sand.

The well included a high-temperature, high-pressure (HTHP) plug, used to isolate an undesirable area lower down in the well from the producing region above. After sand removal was ineffective, the operator hypothesized that the pressure effects during shut down and restart had caused the plug to move up the well and become stuck above the top perforation at the HUD. This scenario would cause an obstruction at the HUD and halt production. A lead impression block returned ambiguous results that could be the top of the HTHP plug, supporting the HTHP plug hypothesis.

The operator’s options to inspect the HUD and remove the HTHP plug were severely limited due to the completions ID limitations, contents, and high temperature of the well. The wellbore was primarily filled with gas, with a column of murky fluid of unknown composition at the HUD.

Objectives Achieved

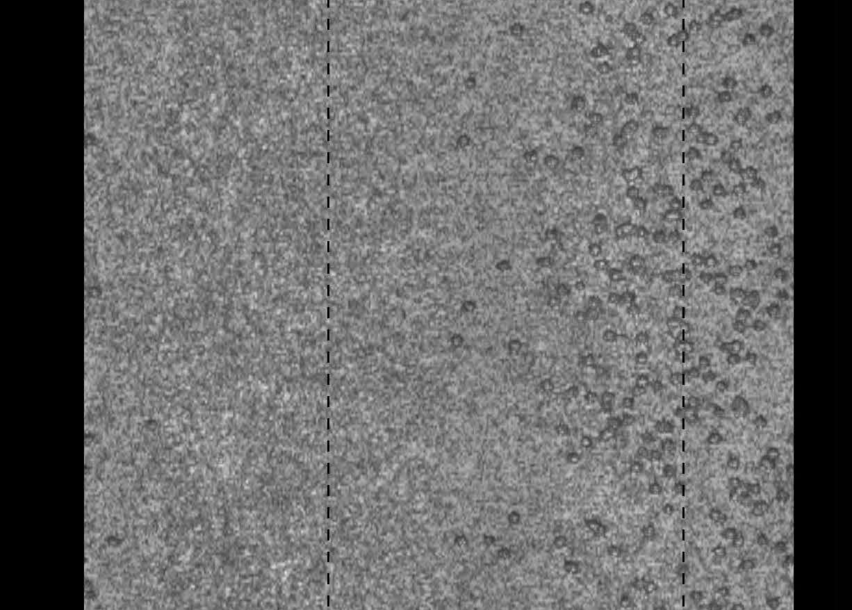

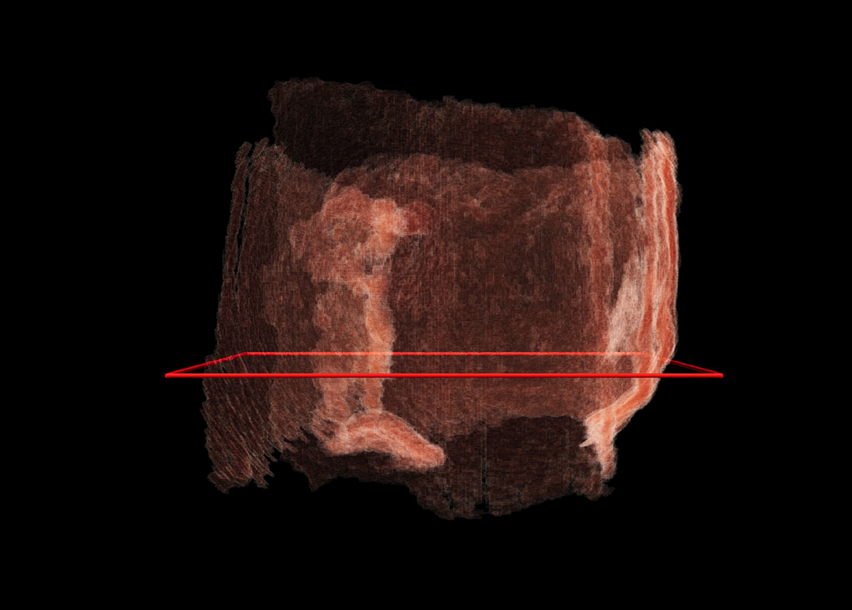

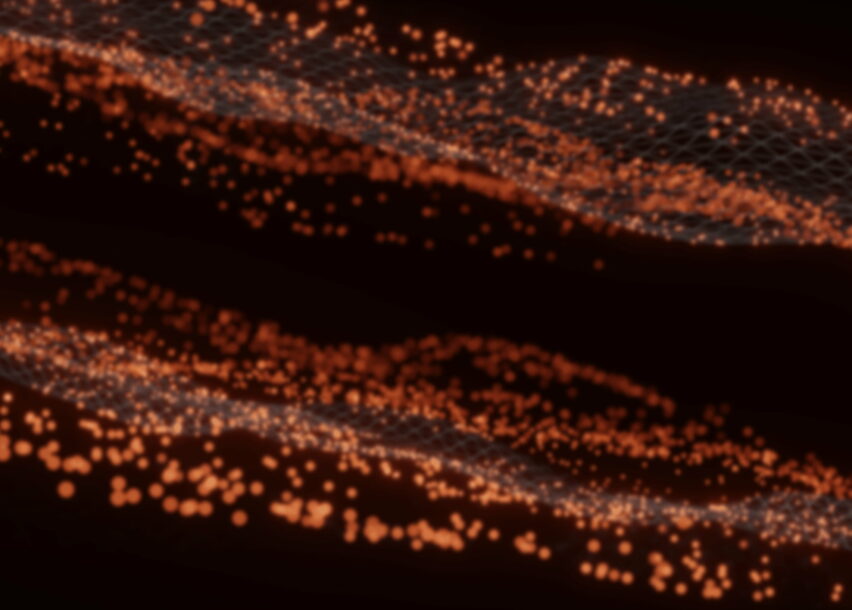

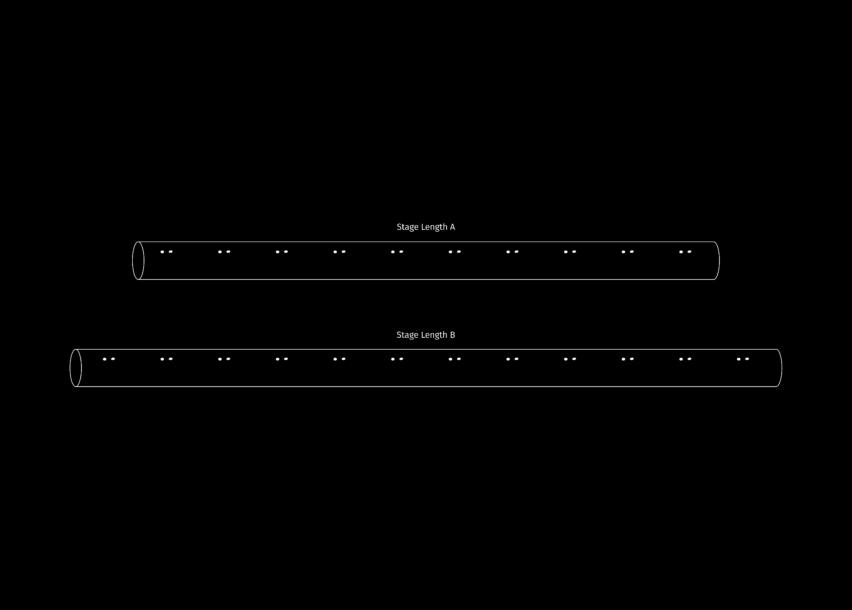

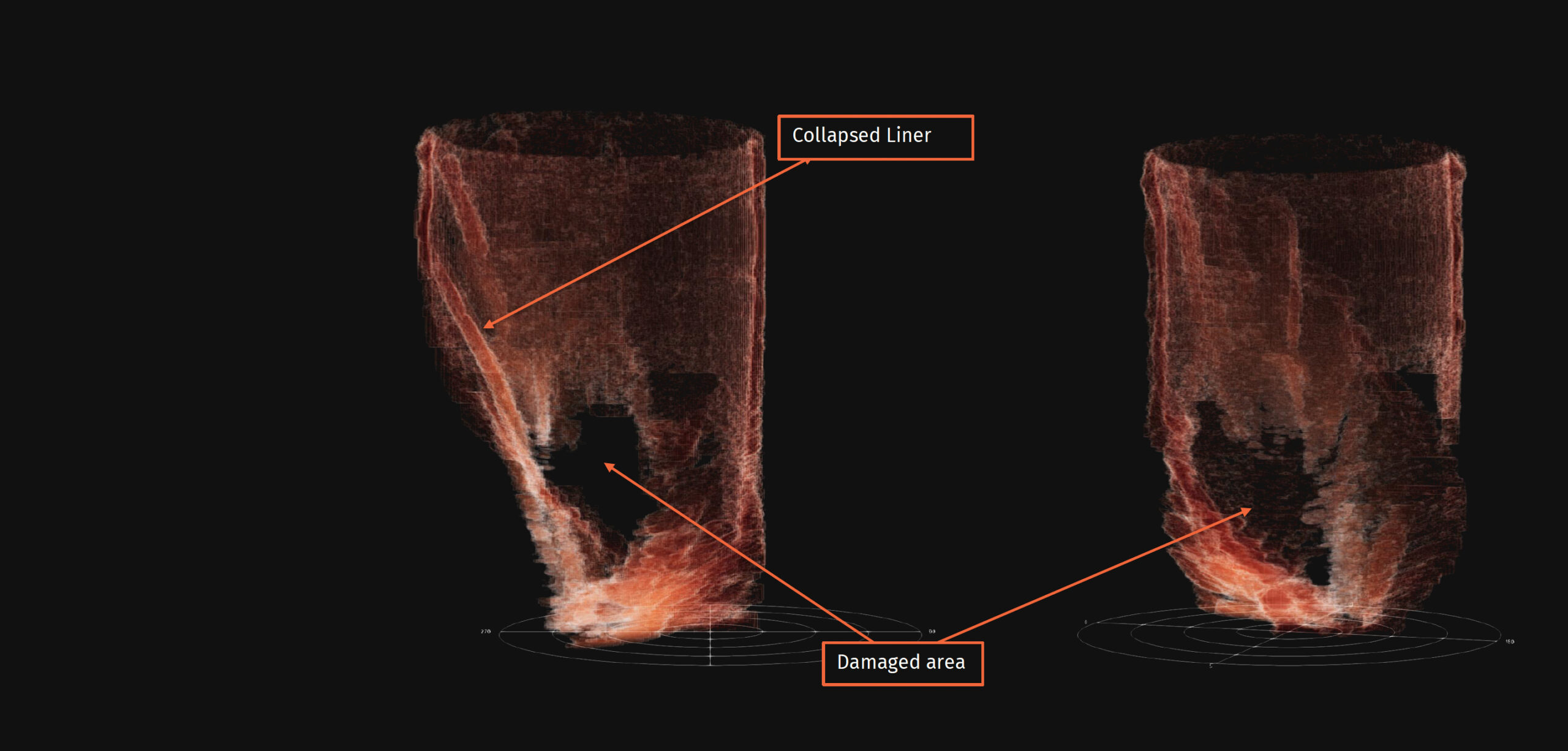

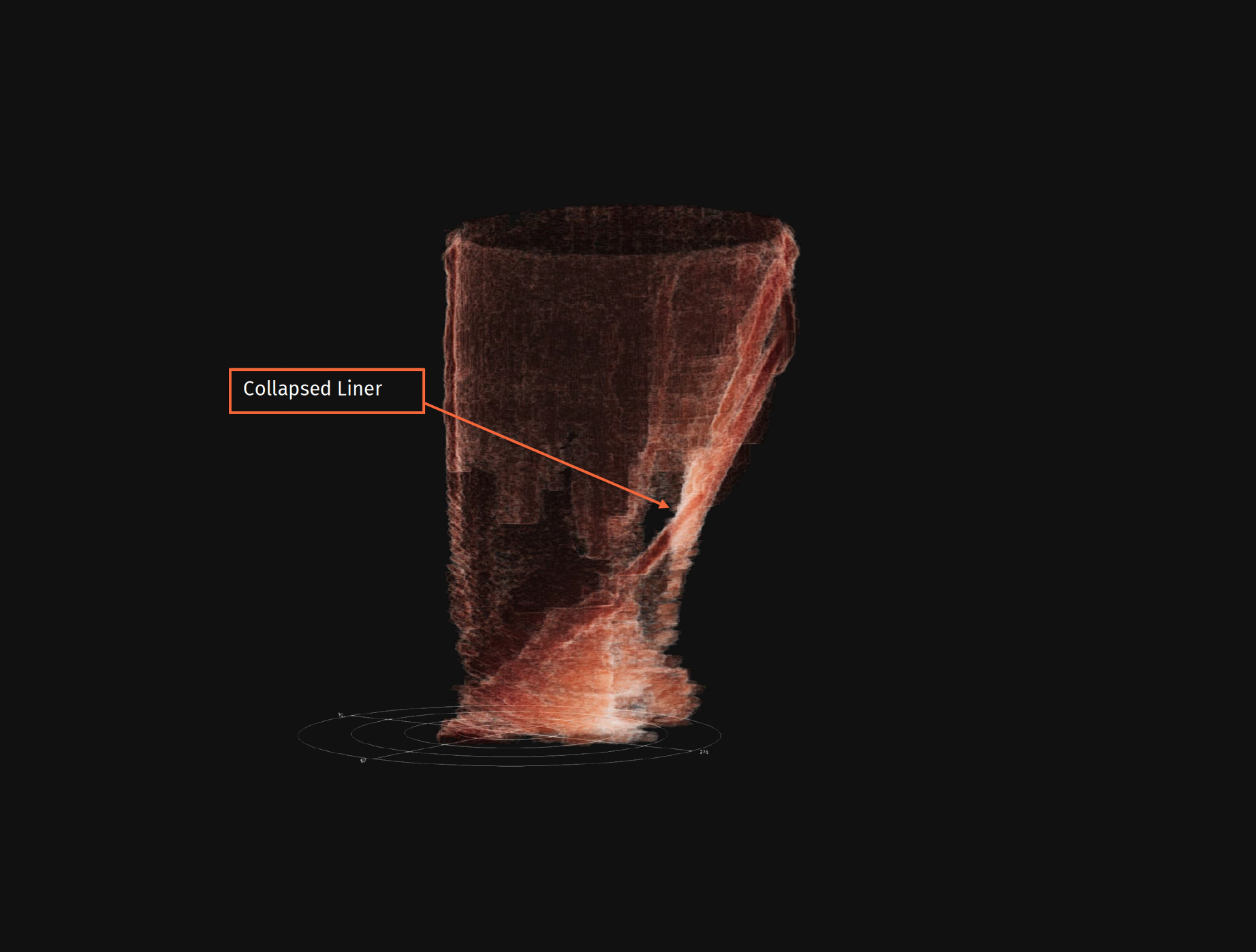

The operator asked DarkVision to scan the HUD with HADES-F. Despite the challenging wellbore conditions, DarkVision successfully captured a comprehensive 0.25mm resolution 3D scan of the obstruction and surrounding casing.

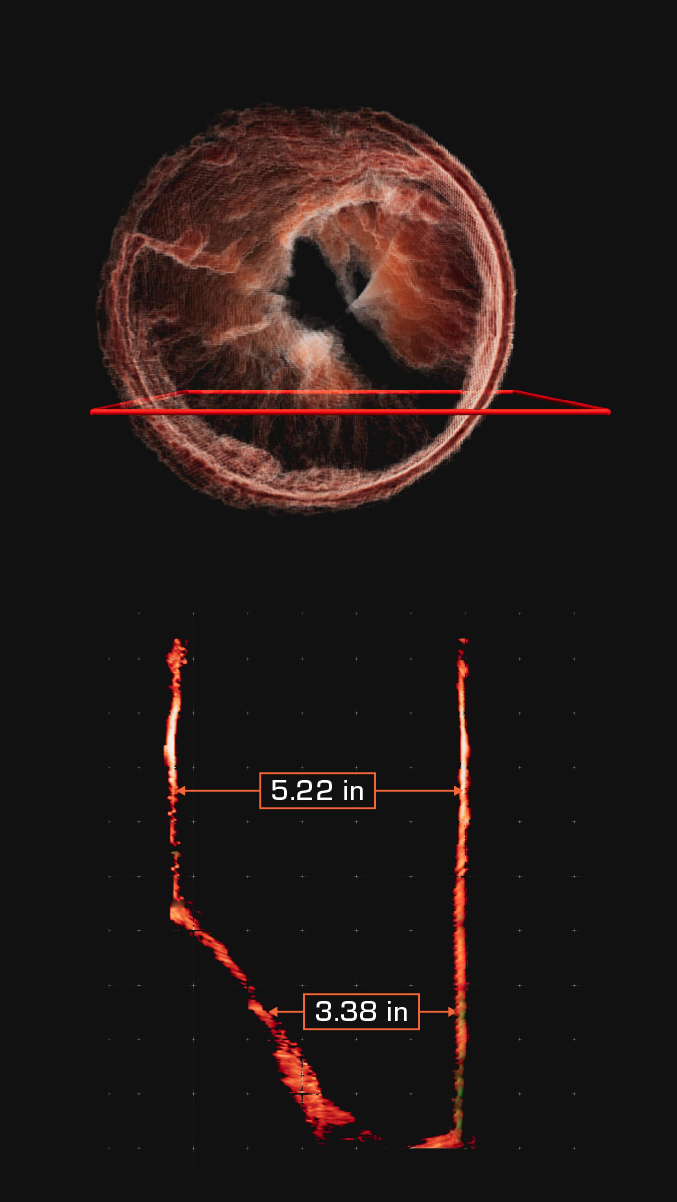

A full report was delivered to the operator within 6 hours upon rig down. Based on the clear images provided by DarkVision, it was apparent to the operator that the obstruction at the HUD was a parted 7-inch liner and not an HTHP plug as they had expected.

Results

Once they knew for certain that the obstruction was a parted liner, the operator was able to perform a pressure test of the well. They verified 100% communication between the well and reservoir and successfully returned the well to production. By having the facts instead of assumptions, the operator was able to regain production on this high value well utilizing existing well infrastructure.