Unlock content

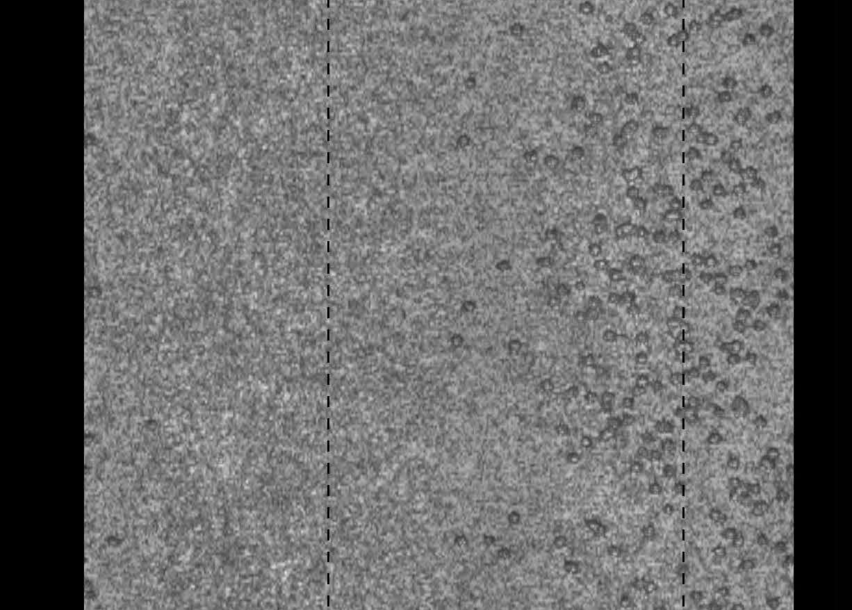

Gain a significant step-change in resolution, accuracy, and ability to evaluate wells for integrity risks with the highest resolution and best coverage available.

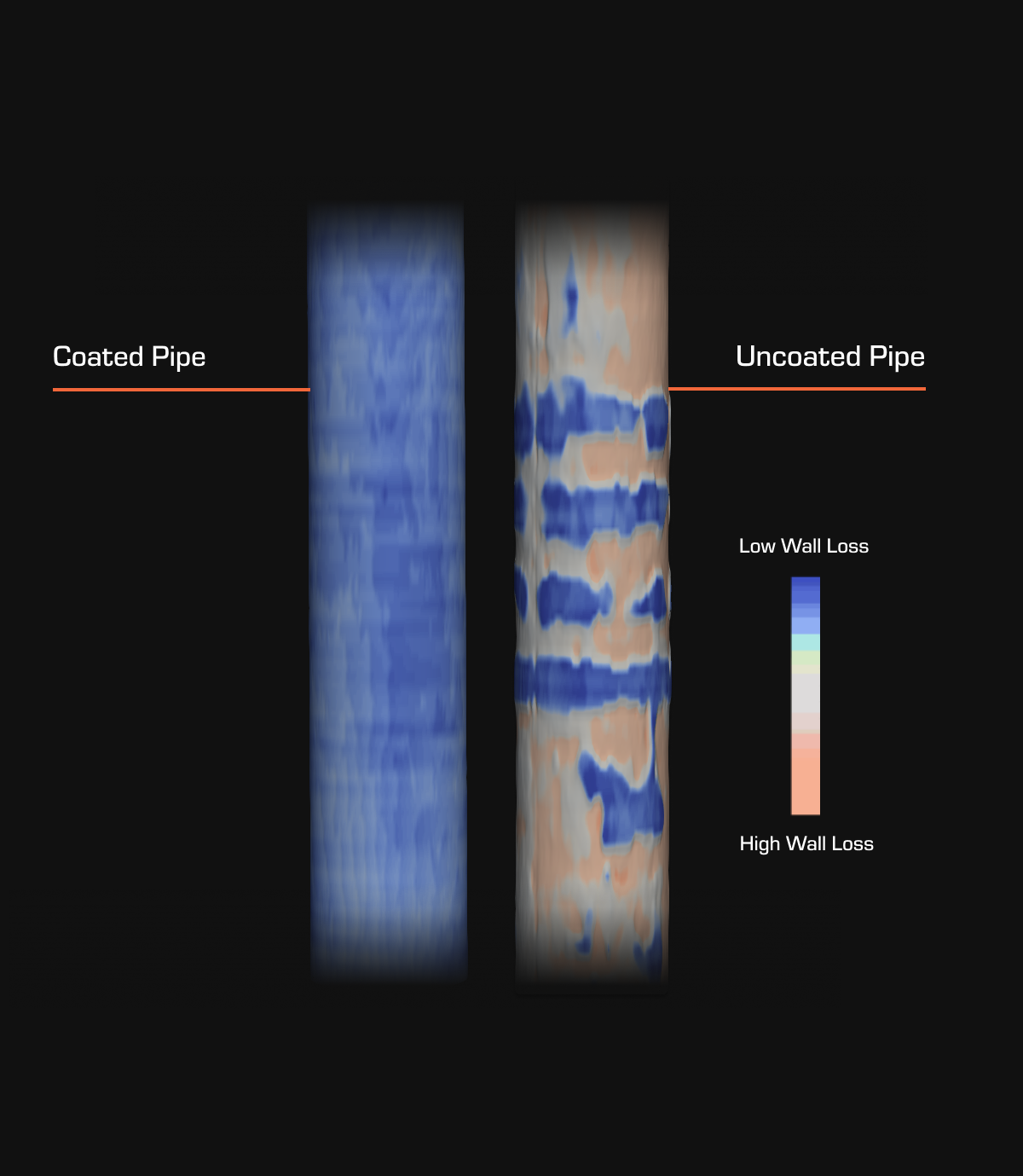

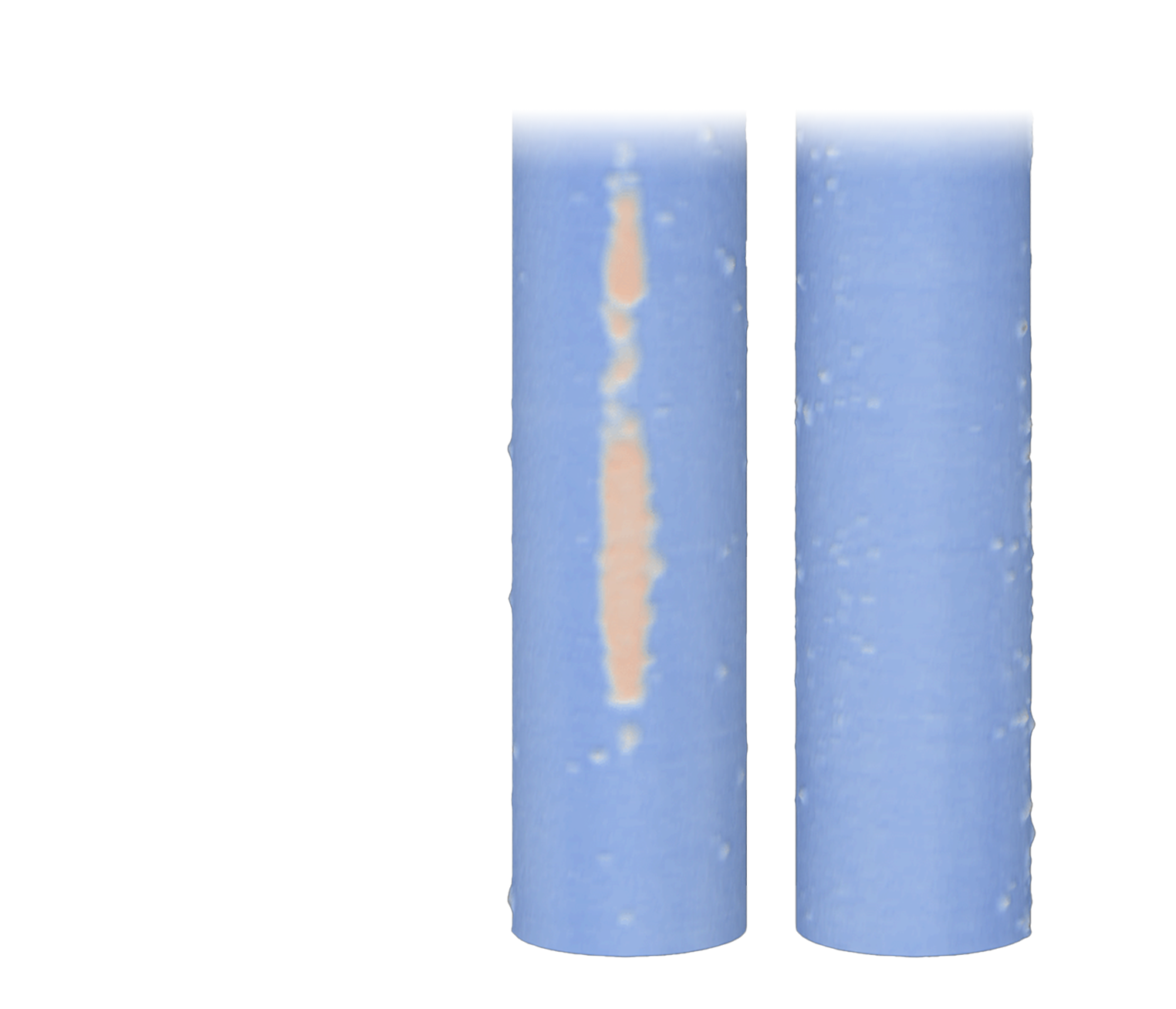

Quantify casing thickness, corrosion, and mechanical damage by measuring both inner diameter and outer diameter wall loss to extend well life, optimize workover schedules, and manage gas storage pressure ratings more effectively.

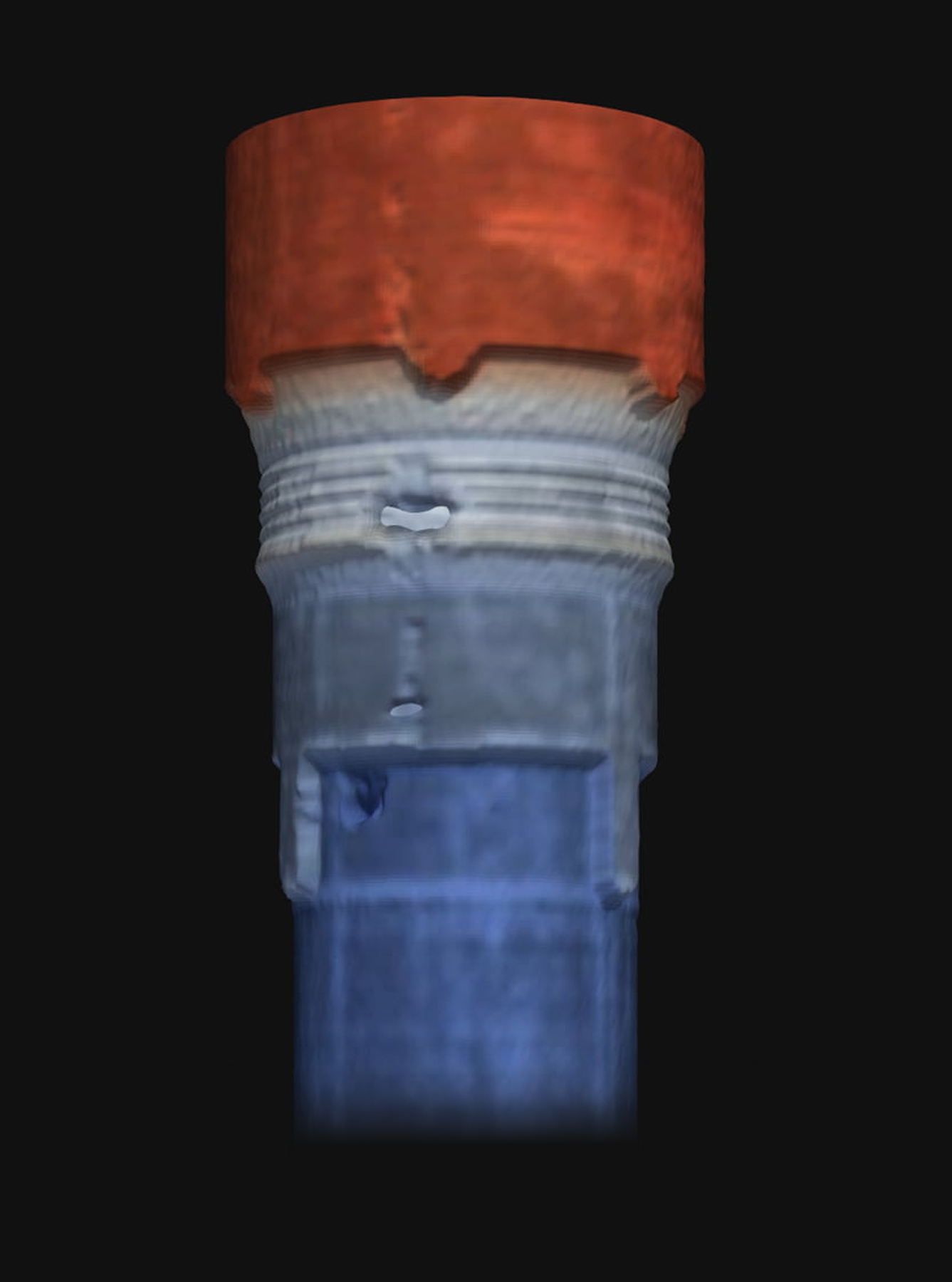

Evaluate joints that are over-torqued, improperly connected, have damaged threads, or are in a compromised state that may fail at higher pressures.

Diagnose complex surface and downhole component failures. Whether it’s a wellhead, subsurface safety valve, liner hanger, or ICD – we will find damage, deformation, ovality, and leak paths like no one else.

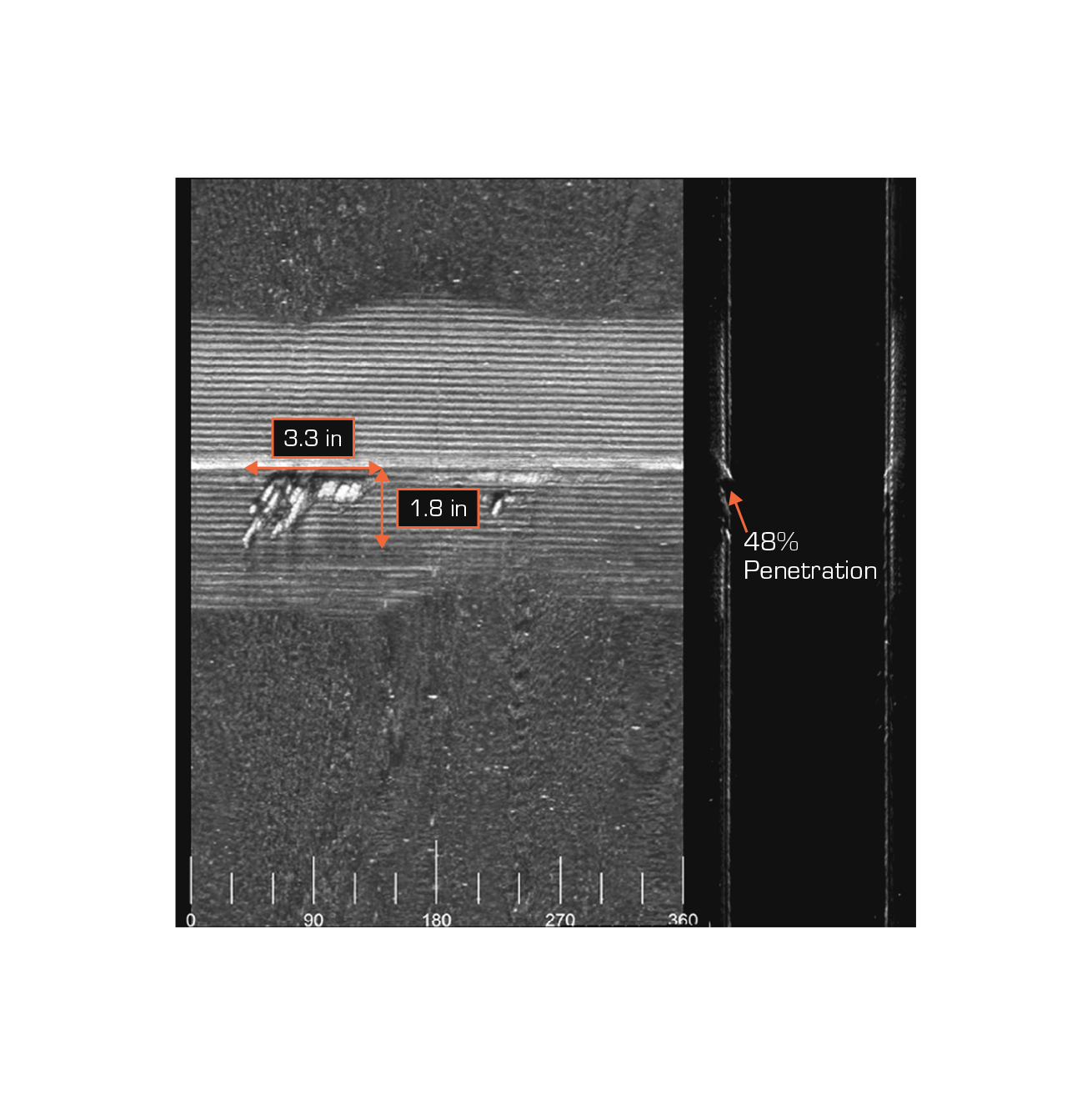

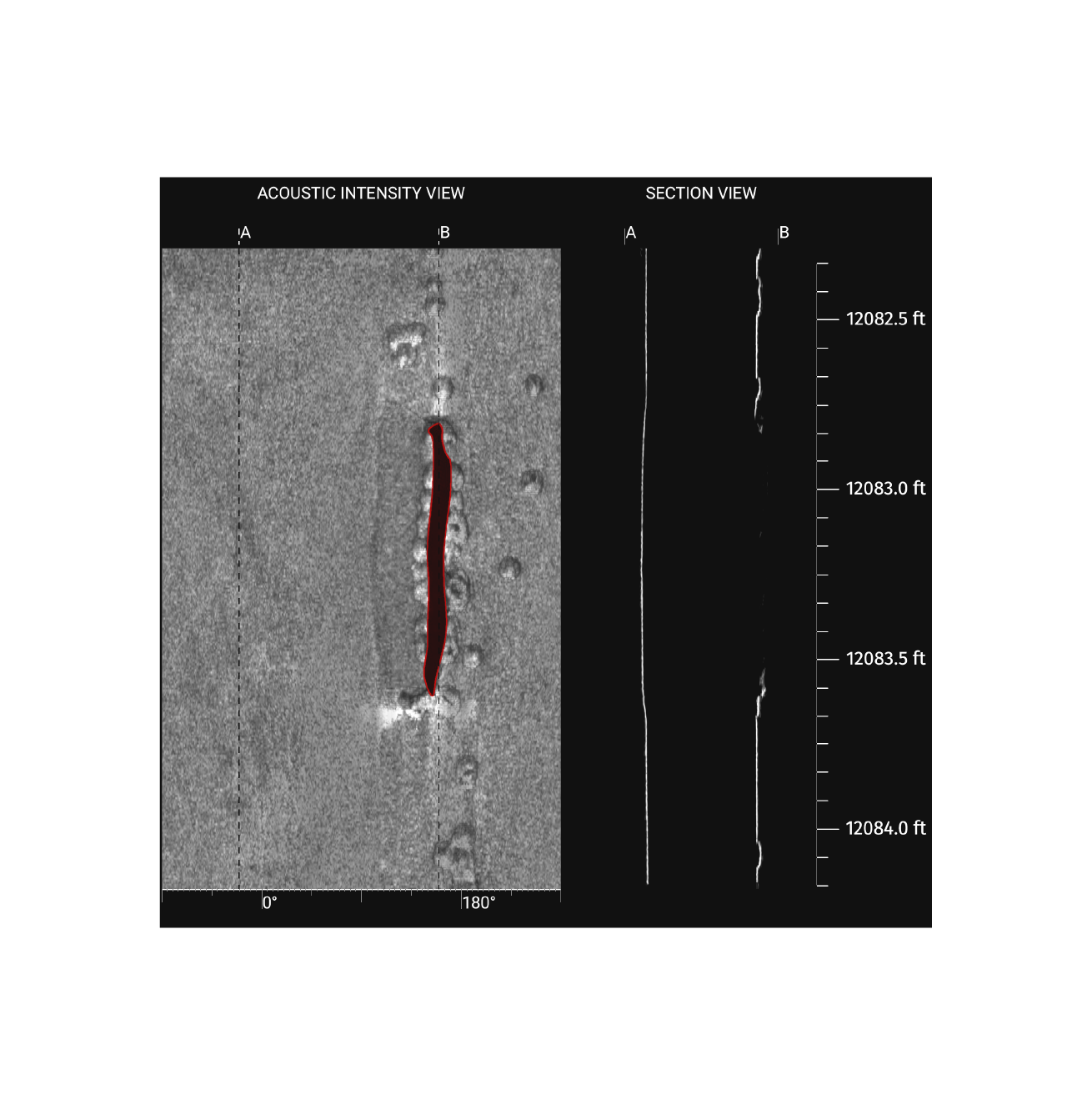

Never miss another defect. Find axial splits, cracks, and weldseam damage that does not have sufficient metal removed to be detected by other tools.

In this paper, DarkVision presented how to de-risk well operations by getting detailed sub-millimetric wall thickness profiles to perform advanced burst pressure analyses. The paper reveals how every pressure-limiting defect on both the ID and OD are measured in 3D and highly accurate Riverbottom profiles of every defect are generated.

Read the Paper