Unlock content

Share this

Athabasca Oil Sands

HADES-R™

A failed routine pressure test following the removal of an electronic submersible pump prompted an established Albertan operator to investigate the cause of the failed pressure test. Multiple wireline diagnostic tools were run to diagnose and determine the failure cause – all of which returned ambiguous results. DarkVision was brought in to conduct a well integrity inspection and provide a definitive assessment on the root cause.

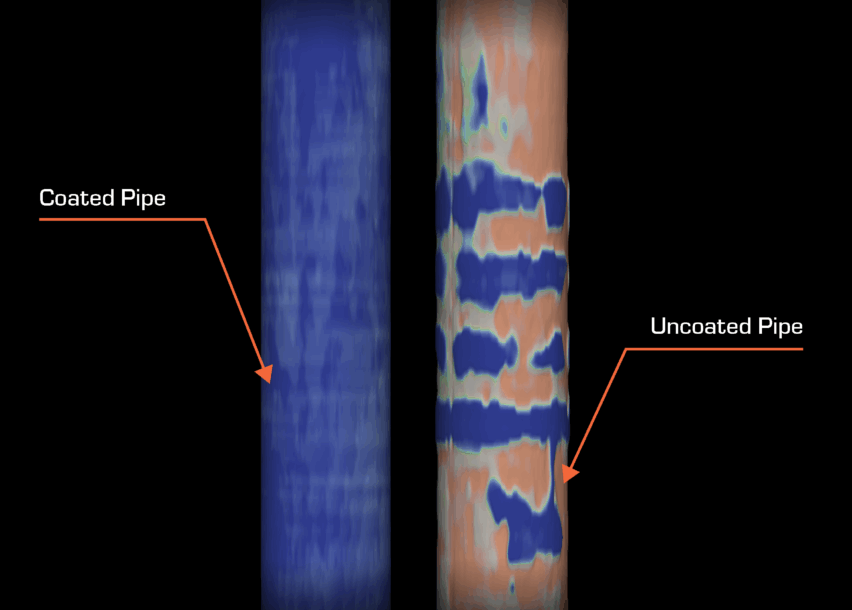

Darkvision’s HADES-R™ high-resolution acoustic imaging tool logged the well to a depth of 650 m, providing the operator with an ultrahigh-resolution view of the casing area in question. By capturing a full circumferential 3D scan of the entire vertical, DarkVision recorded and accurately measured casing wall loss. Casing breaches were identified as the cause of the pressure test failure. The inspection also revealed that drill pipe wear reducing the casing wall thickness to below 50% of nominal and severe pitting was present throughout the build section of the well.

With the detailed analysis provided by DarkVision, the operator knew the exact location and size of each casing breach, enabling them to quickly apply the appropriate patches. A subsequent pressure test confirmed that well integrity had been restored.

Operators are continuously seeking ways to maximize recovery while controlling costs. Maintaining well integrity is key to achieving their goals. Unlike the inferred sizing methods used by magnetic and optical tools, DarkVision’s 3D scans are built from direct measurements.

Darkvision’s scans are more detailed than those made with magnetic or caliper tools, ensuring unambiguous results on the first run. The high-resolution 3D model delivered by DarkVision empowers operators to confidently make informed and timely decisions on well maintenance, minimizing time spent diagnosing well integrity issues, and maximizing ROI on OPEX spend.