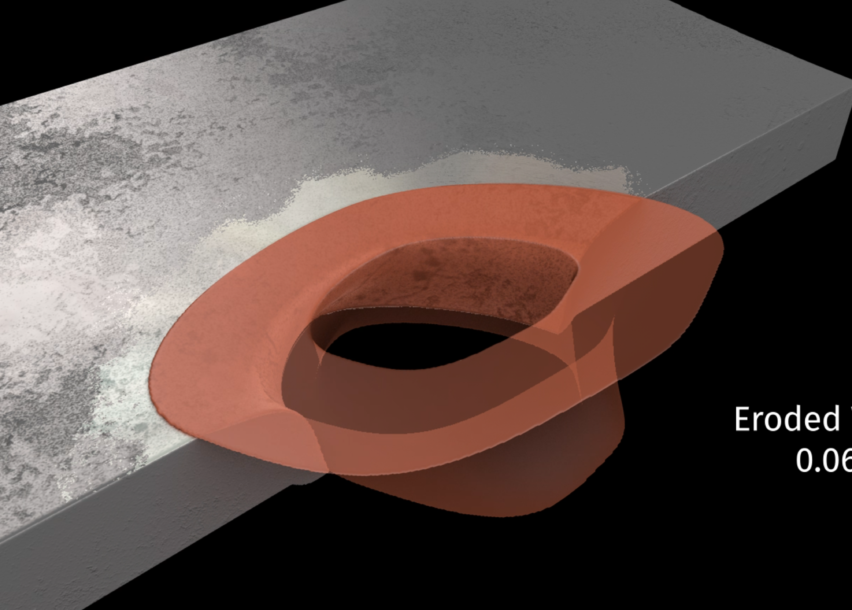

At this year’s SPE Annual Technical Conference and Exhibition (ATCE) DarkVision presented its newest technical paper on how to de-risking well operations by getting detailed sub-millimetric wall thickness profiles in the field to perform advanced burst pressure analyses. The paper reveals how every pressure-limiting defect on both the ID and OD are measured in 3D and highly-accurate Riverbottom profiles of every defect are generated. This enables the use of improved Effective Area and RSTRENG methodologies over the traditional Barlow and Modified B31G methods to calculate burst pressure. This means higher operating pressures can be safely used for more effective completions and increased production.

Read the full whitepaper: “High-Resolution Acoustic Imaging for Submillimetric Casing Thickness Quantification and Advanced Effective-Area-Based Burst Pressure Analyses” to get the full story.

Abstract

For downhole casing integrity applications, high-resolution acoustic imaging is a novel approach for quantifying casing thickness, corrosion, and mechanical damage defects by measuring both inner diameter and outer diameter wall losses. The technology deploys high-density solid-state arrays with up to 512 transducers to achieve sub-degree azimuthal and sub-millimetric axial resolutions with casing thickness measurements down to a minimum thickness of 0.07 in with an error of ±0.005-in. In this study, we discuss the technological advancements, details of laboratory validation results, exploration of burst pressure calculation methodologies, and a field case study based on the novel technology.

The high-density solid-state transducer array uses acoustic signals to measure the casing thickness and radial measurements in a single pass. The resulting 3D point cloud of data is analyzed using image-processing-based machine learning algorithms. The validation data are collected from multiple machined and field samples. The machined defect dimensions are varied to test the detection, sizing, and accuracy of the platform. A field-based case study is presented to compare high-resolution acoustic imaging data with computed tomography scan data. To demonstrate the advantages and sensitivities of using high-resolution datasets and high-accuracy burst pressure methodologies, examples of RSTRENG software burst pressure analyses are provided.

The high-resolution acoustic imaging platform offers fundamental improvements over legacy magnetic flux leakage (MFL) and single-element ultrasound-based tools. Acoustic technology relies on direct measurement principles and results are not inferred through calibration. The time-of-flight-based approach enables the inspection a single casing string comprising different diameters, wall thicknesses, and materials in a single log run. The technology is pipe material agnostic and directly measures the casing thickness of ferrous and nonferrous metals. The electronic platform enables the capture and storage of submillimetric axial resolution, which provides details of the penetration profiles of all defects. High-resolution and spatially registered datasets are leveraged to conduct effective area, RSTRENG, and modified B31G burst pressure calculations with significantly improved defect identification, penetration quantification, interaction rule application, and shape characterization. The advancements presented in this paper are highly pertinent to gas storage and carbon sequestration operators, seeking integrity management advancements. The real-world benefits of the presented technology are the ability to extend well life, optimize workover schedules, and manage gas storage pressure ratings more efficiently.