At this year’s 2025 Pipeline Pigging and Integrity Management Conference (PPIM), DarkVision launched Kraken – a new pipeline tool which will shape the future of pipeline integrity. The centerpiece of this launch is the following paper which introduces the technology to industry as well as presenting findings from field runs with Flint Hills Resources. Following PPIM, a link to the complete paper will be posted.

Additional information about Kraken can be found here.

Abstract

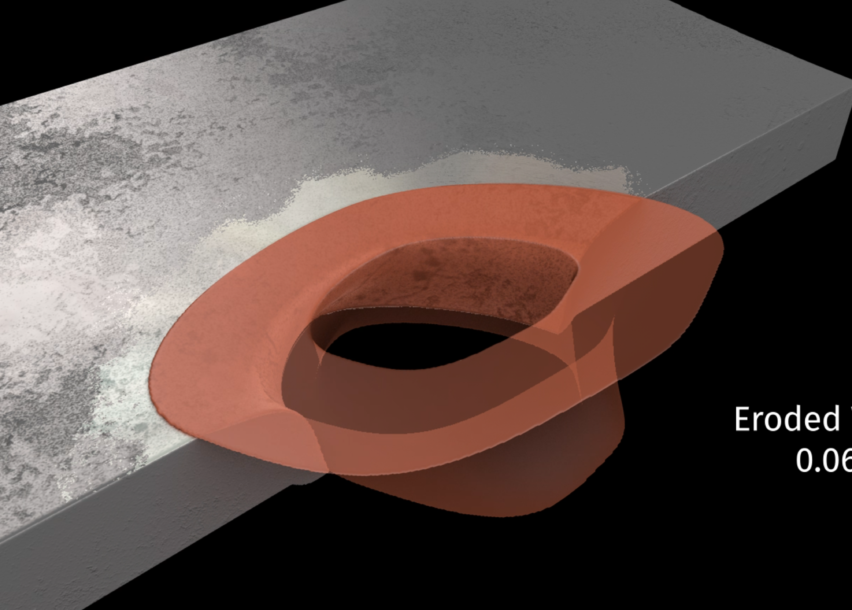

Pipeline operators are gaining significantly more intuitive results with a novel In-line Inspection tool that comprehensively evaluates every major anomaly type – metal loss, axial cracks, and dents – in a single run. This technology represents a fundamental improvement in resolution and the ability to understand combined threats impacting pipelines. Direct 3D measurements reveal the shape and orientation of anomalies that enable operators to better understand the root cause and context of the anomaly. This direct imaging method is not only more intuitive for industry, but it also overcomes legacy amplitude-based inferred measurement methods that have limitations when measuring crack morphologies.

The tool leverages the latest developments from phased array in-ditch based handheld systems, medical imaging, and upstream oil and gas ultrasound imaging technologies to bring ultrafast imaging rates with 0.5mm axial resolution, and 0.25mm circumferential resolution at line speeds exceeding 3 meters/second. Over 6,000 independent sensors mounted on encoded carriers detect and size metal loss, axial cracks, and dent information from a single registered pass.

This paper presents and validates the technology in accordance with API 1163. A 400-meter continuous flow loop was engineered and constructed to test the tool’s endurance and validate the tool’s performance over a variety of anomalies including electrical discharge machined (EDM) notches, manufactured cracks, and wall loss. These results are validated against industry standard tools including a metrology-grade laser scanner and a phased-array ultrasound handheld tool. Additionally, the results related to identification and measurement of challenging anomalies such as stress corrosion cracking (SCC), hook cracks and lack of fusion that were removed from Flint Hills Resources pipelines are presented. Lastly, findings from a full-scale deployment in a segment of Flint Hills Resources 16″ transmission pipeline are summarized.

About the Authors

Thank you to our authors: Greer Simpson; Corey Richards; Carlos Costa (DarkVision); Aaron Schwing; Jason M Moritz (Flint Hills Resources).

Greer Simpson, Director of Product, DarkVision

Greer Simpson, P. Eng, is the Director of Product for DarkVision – a technology company focused on developing, manufacturing, and deploying high-resolution acoustic imaging solutions for downhole and pipeline inspection applications. Greer oversees the technical and strategic roadmap of DarkVision’s product lines, including the expansion of the technology into new regions and market verticals. Prior to DarkVision, Greer served as a Production Engineer for multiple upstream operators in Western Canada.

Corey Richards, Director of Business Development, DarkVision

Corey is an Electronics Engineering Technologist with over 15 years of experience in inline inspection. He has worked in field operations, sales, and business unit management, overseeing field services and unpiggable pipeline solutions, including supporting business growth in Asia and Oceania during his five years in Germany. Currently, as the Director of Business Development at DarkVision, he focuses on advancing inline inspection (ILI) and acoustic imaging technologies.

Carlos Alberto da Costa Filho, Ph.D, Research Manager, DarkVision

Carlos is an applied scientist with over 10 years of experience in industrial imaging, and over 30 peer-reviewed works published. At DarkVision, he holds the role of Senior Researcher and is also the lead of the Machine Learning Engineering team. Carlos has a bachelor’s and master’s degree in mathematics, and a Ph.D in Geophysics.

Jason Moritz, Senior Integrity Engineer, Flint Hills Resources

Jason Moritz is a registered Professional Engineer in the State of Illinois with 15 years of experience in the pipeline industry. He graduated from Iowa State University in 2008 with a Bachelor of Science in Construction Engineering. At Flint Hills Resources, Jason serves as a Senior Integrity Engineer within the Pipelines and Terminals Mechanical Integrity and Reliability group. For the past 10 years, he has focused on managing the implementation of Integrity Management programs for Flint Hills Resources’ pipeline network.

Aaron Schwing, Director Asset Integrity & Reliability, Flint Hills Resources

Aaron joined Koch Industries Pipeline Division in 1996 after earning a Bachelor of Science degree in Electrical Engineering from Oklahoma State University. He has held numerous individual contributor and leadership roles in the areas of SCADA, Automation, Engineering, and Asset Integrity & Reliability. In his current role, Aaron is responsible for Flint Hills Resources Pipelines & Terminals Mechanical Integrity and Reliability programs covering ~4000 miles of pipelines and facilities.