At this year’s 2025 HFTC, DarkVision and Oxy presented a technical paper which thoroughly examines how advanced perforation (perf) erosion analysis with three-dimensional (3D) measurements can produce analytical results comparable to fiber.

SPE-223542-MS

The full whitepaper is available here: “Adding Depth: The Superiority of Volumetric Perforation Erosion Analysis for Evaluating Stimulation Performance and Optimizing Completion Designs”

Abstract

Objectives/Scope

Permanent fiber optics and high-resolution acoustic imaging are two diagnostic tools commonly used to assess completion design performance in horizontal wells. Fiber optics offer real-time data at the cluster level but can be costly and prone to mechanical failure. In contrast, acoustic imaging is much more affordable but only captures temporal snapshots of data. This paper thoroughly examines how advanced perforation (perf) erosion analysis with three-dimensional (3D) measurements can produce analytical results comparable to fiber.

Methods, Procedures, Process

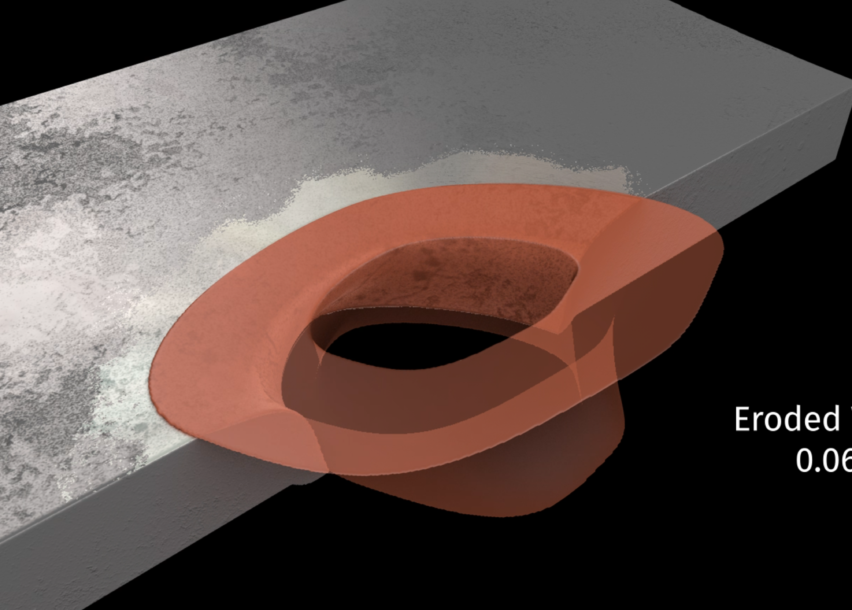

Perf tunnel volumes are calculated using measurements obtained from high-resolution acoustic imaging technology, which has been laboratory-validated against a metrology-grade laser scanner. These measurements are used to generate a novel diagnostic plot that explains perf erosion behavior in conjunction with theoretical growth cases. This plot is also used to empirically determine uneroded perf tunnel volumes for different regions around the borehole, which are subtracted from eroded volumes to calculate growth at the perf, cluster, and stage levels. The growth volumes are then used to calculate treatment uniformity with respect to inferred proppant placement for different stage configurations.

Results, Observations, Conclusions

Treatment uniformity values determined from volumetric perf erosion analysis are strikingly similar to those determined from permanent fiber optics using Distributed Acoustic Sensing (DAS) data collected in real-time during stimulation. In the case of a horizontal Niobrara well analyzed with both diagnostic technologies, the conclusions independently determined from both datasets yielded the same answer in terms of which stage configuration should be utilized for future field development plans. Hydraulic fracture profiles (HFPs) were also generated for stages that had all perf measurements available for analysis. When these HFPs were directly compared to those generated from permanent fiber optics for the same stages, they tended to show a tremendous amount of similarity with respect to inferred cluster-level proppant placement and treatment bias. This alignment between fundamentally different diagnostics not only demonstrates the strength and veracity of volumetric perf erosion analysis, but it also helps validate the new method of empirically determining uneroded perf tunnel volumes using 3D measurements.

Novel/Additive Information

Although acoustic imaging technology has been used extensively for several years, erosional analyses have typically been performed using exit hole measurements exclusively. Only recently has 3D volumetric perf erosion analysis been evaluated. It is clear from the learnings that exit hole measurements alone do not account for all the subtle nuances associated with proppant placement and erosional phenomena. These additional measurements allow perfs to be represented in 3D space, which has helped bridge the gap between different diagnostics that historically lacked alignment and left operators wondering in which dataset to place their confidence.

Paper Number: SPE-223542-MS

Authors: Matt Jones; Charles Bourgeois; Trent Pehlke; Anthony Battistel; Cole Coupland; Gaurav Handa; Jon Nilemo; Kenneth Tan.

Read the full white paper: “Adding Depth: The Superiority of Volumetric Perforation Erosion Analysis for Evaluating Stimulation Performance and Optimizing Completion Designs” to get the whole story.