The following is a summary of the paper “Assessing the Impact of Oriented Perforating Strategies and Frac Plug Performance in DJ Basin Wells”, presented at URTeC 2024.

Objectives

In the DJ Basin, Chevron wanted to determine the impact of perforation orientation, orientation system, and plug type: on key stimulation performance metrics and oil production rates. They performed a multi-well assessment to measure perforation efficiency (PE), cluster efficiency (CE), and uniformity index (UI) to assess the stimulation’s performance and correlated oil production rates to the manipulated design variables.

The analysis was broken into 3 phases which assessed oriented versus phased perforating, plug type and orientation direction respectively.

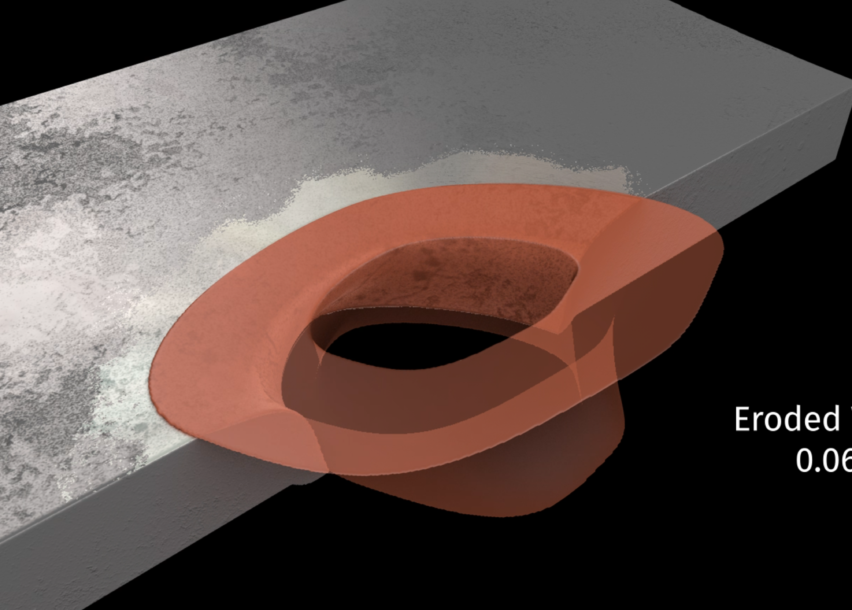

High-resolution acoustic imaging was used to assess and quantify the impact of these variables on fracture performance in terms of the UI, CE, PE, and zonal isolation by visualizing and measuring erosional wall loss at plug sites.

Key Findings

In phase 1, 72 stages were scanned across 3 wells. Internally oriented perforating systems achieved the most consistent orientation with all perforations shot within +/- 45 degrees of the high side. Although the optimal orientation method was clear, 33% of the plug set locations demonstrated casing damage or a full breach, indicating lack of isolation

This conclusion led Chevron to pursue a large-scale plug trial in phase 2. Results from the acoustic imaging analysis paired with surface treatment data from 3,000 plugs indicated the superior performance of composite over dissolvable plugs. Well 4 (which used composite plugs) had the highest UI and CE, and did not exhibit any casing damage. Moreover, the acoustic imaging results revealed two additional key findings: most stages exhibited a heel-side bias and perforations shot at collars often grew into outlier perforations and negatively affected the UI.

Finally, phase 3 revealed that of the 3 orientations tested, the 0-degree oriented design showed a notable improvement in the CE and UI. Data collected quantified the improvements of oriented perforating on perf size consistency and increased production rates.

Conclusion

Knowledge gained from this analysis assisted Chevron in optimizing their completions design for the DJ Basin and resulted in an observable increase in production due to improved phasing design, orientation deployment and the use of composite plugs.

For a more comprehensive overview, read the paper entitled “Assessing the Impact of Oriented Perforating Strategies and Frac Plug Performance in DJ Basin Wells” originally presented at URTeC 2024.