Technology Used

HADES-T

Well Information

- Well Type

- Salt Cavern Gas Storage

- Casing Diameter

- 16-inch

Application

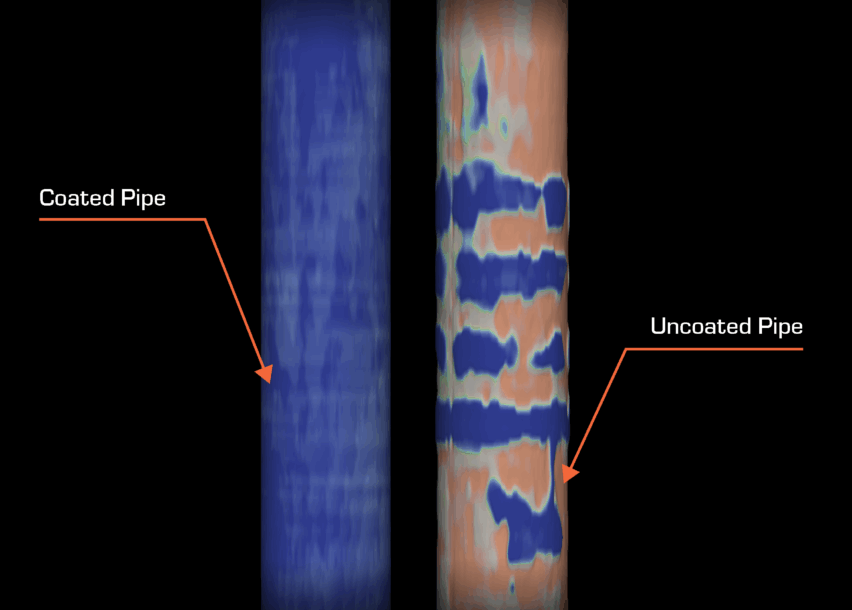

A salt cavern operator wanted to verify the proper installation of an expandable liner in a 16-inch production casing string. They decided to run DarkVision to perform this verification and to evaluate the performance of DarkVision in large diameter pipe. They were especially interested in inspecting the integrity of the connections which MFL is incapable of evaluating, the extent of any internal and external corrosion, and the severity of ovality in a high stress environment.

Objectives Achieved

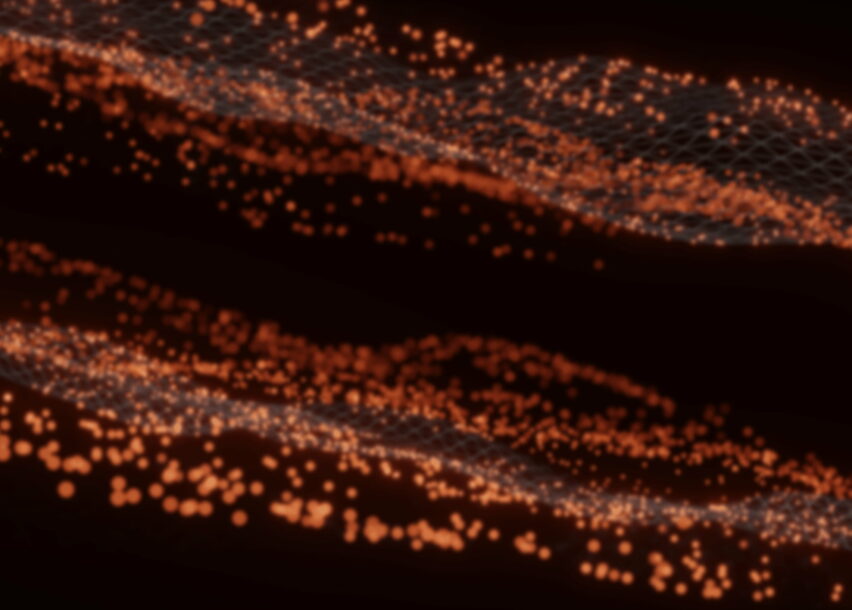

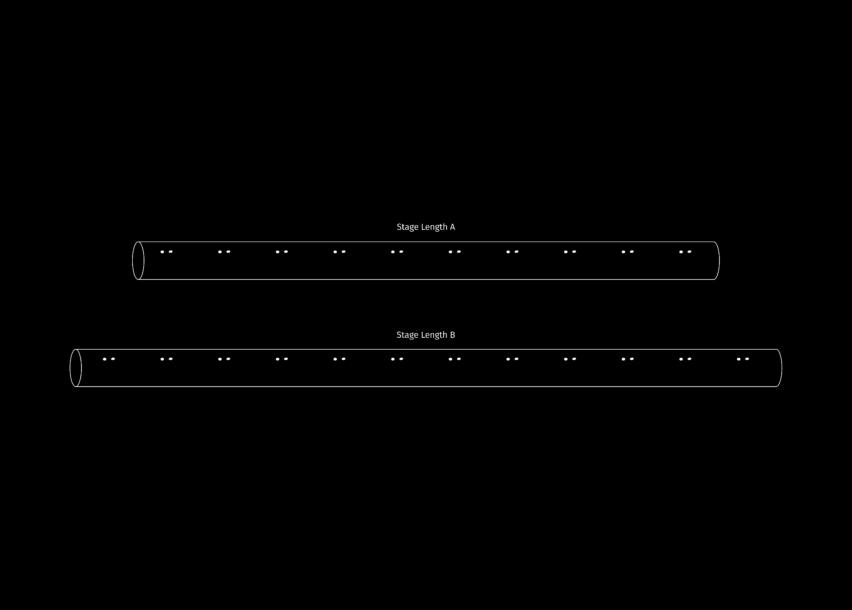

DarkVision comprehensively scanned the entire casing string – from wellhead to the casing shoe – performing an industry first high-resolution acoustic inspection of such a large diameter completion.

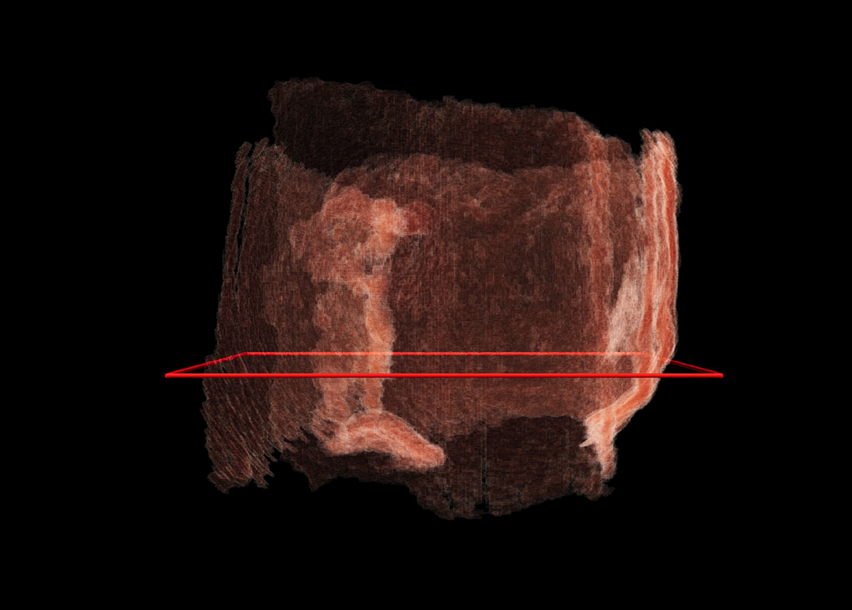

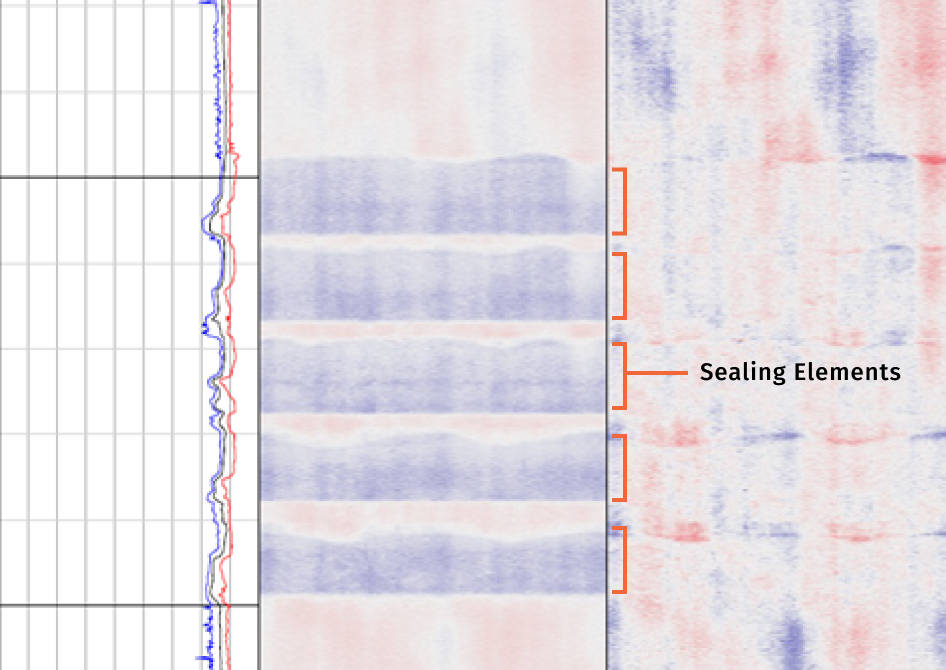

Images of the sealing elements at the top and bottom of the expanded liner are clearly visible above and below the protected interval, indicating that the liner was set properly at the correct depth. The 2D log also showed the anticipated ovality through the protected interval, indicating that the liner was fully expanded and properly flush against the ovalized casing in that region. DarkVision also verified the pass-through diameter of the expandable liner, which matched manufacturer specifications.

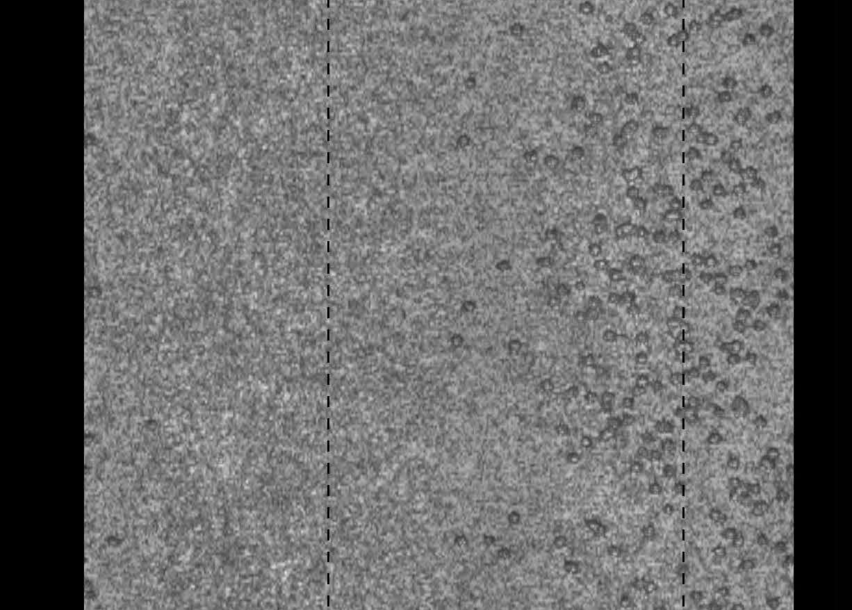

DarkVision’s scans revealed an unreported restriction due to debris below the expanded liner. The operator confirmed this was the location of the cement plug set during liner installation.

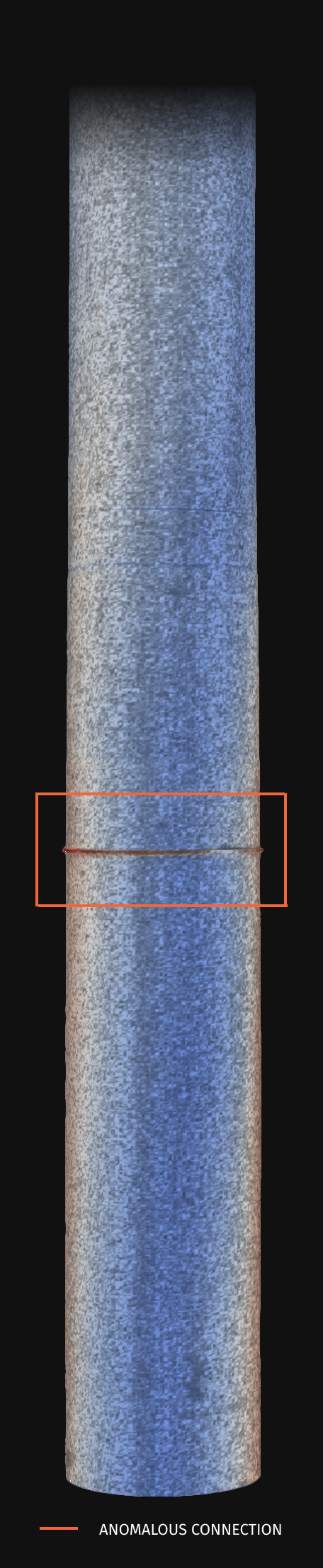

DarkVision also found that, while most connections were in good condition, uniform wall loss of 0.85” was measured at one of the welded connections. The images showed a uniform depression, with no lateral growth, and the surrounding casing in good condition. The operator used this information to determine that the wall loss was likely due to a weld defect when the connection was installed. Understanding the root cause of the wall loss at the connection helped the operator understand and quantify the impact of this defect on the integrity of the casing and avoid unnecessary remediation.

Results

Based on the well integrity report provided by DarkVision, the operator was able to confirm the expanded liner was properly set over the correct interval and the post expansion ID of the liner met the manufacturer’s specifications. In addition, the high-resolution direct measurements and intuitive visualizations provided valuable information to help third-party engineering contractors understand the stress and strain profiles in the well.