Unlock content

Share this

Montney Formation

HADES-R™

Wellhead and Wellhead Tools

Wellhead erosion resulting in a loss of pressure containment has significant environmental, safety, and cost impacts. While conducting a perforation erosion and well integrity inspection, an established Montney operator also sought to assess the condition of their wellhead equipment. DarkVision provided the operator with detailed wellhead erosion measurements.

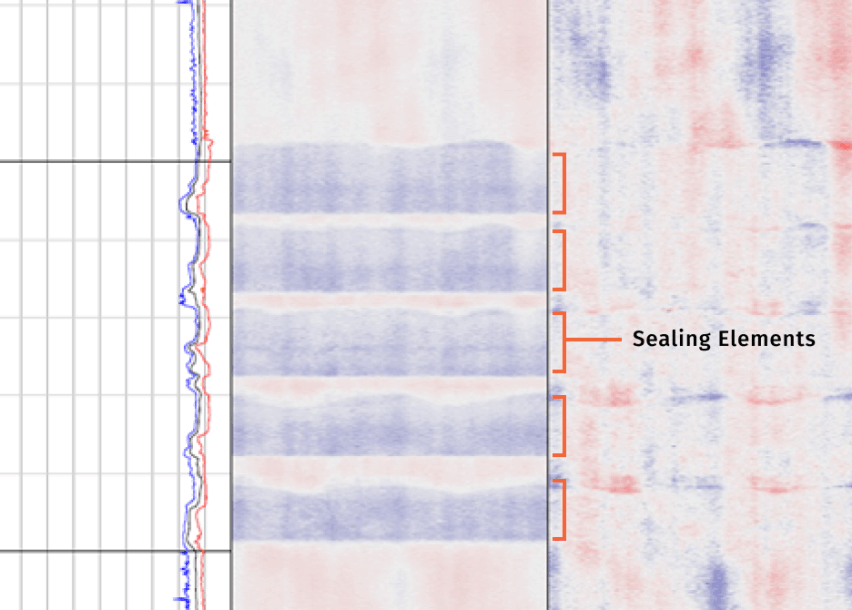

The wellhead was scanned using DarkVision’s HADES-R™ high-resolution acoustic imaging tool. The resulting circumferential 3D scan yielded detailed measurements. The inspection revealed severe erosion on the wellhead flowback cross, and moderate erosion at the side outlets and lock screws. The master valve was in good condition. While technically not part of the wellhead, the tool trap and wireline blowout preventer were also inspected and found to be in good condition.

Ensuring safe and reliable wellbore containment is crucial to well operations and meeting regulatory requirements. Appropriately scheduled preventative maintenance and repairs of surface equipment minimizes the costs and and risk of unnecessary non-productive time by addressing potential integrity issues before they become uncontrolled releases. The wellhead condition data provided by DarkVision enabled the operator to optimize their maintenance schedule as they altered their frac fluid composition and completion strategy.

Thorough wellhead inspection provides operators with an accurate understanding of the impact different frac fluid, proppant types, and pump rates have on their surface equipment. A high-resolution post-frac scan serves as accurate baseline for future corrosion monitoring. By accurately modelling erosion and corrosion rates, operators can make informed decisions to maximize the lifespan of their wellhead equipment and minimize the health, safety and environmental risks of a spill.

By clicking Submit you’re confirming that you agree and consent to our Terms and Conditions.