At this year’s 2024 SPE Hydraulic Fracturing Technology Conference and Exhibition (HFTC) DarkVision presents a new approach to evaluating and quantifying the integrity of casing for refrac operations. This is 1 of 2 technical papers published by DarkVision at HFTC 2024. This technical paper describes the latest methods to comprehensively assess the condition of a well and determining the best course of action to optimize and increase production rates.

SPE-217768-MS

Full whitepaper available here: “On Track for Refrac: Targeting Under-Stimulated Stages and Assessing Casing Integrity Defects with High-Resolution Acoustic Imaging”

Abstract

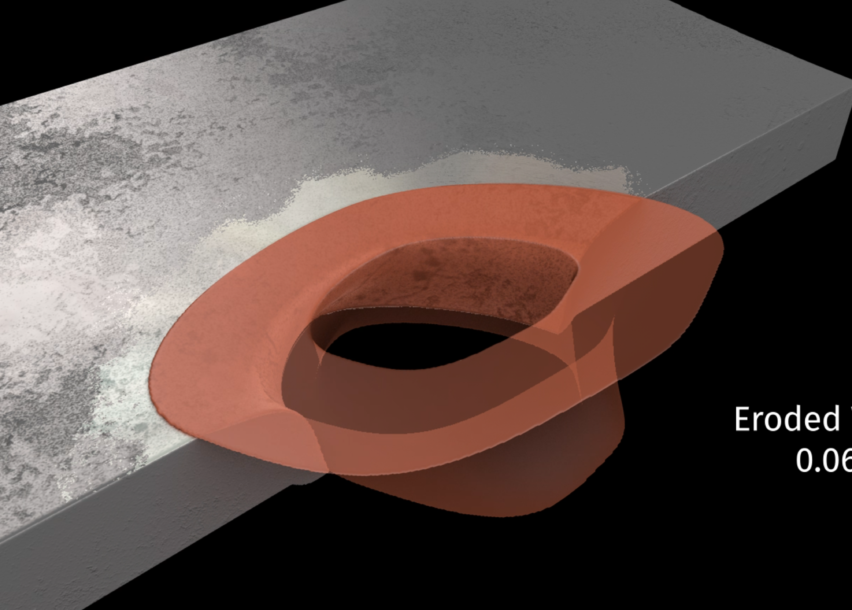

Fracturing technology and industry knowledge garnered over the past decade have unlocked the viability and value of refracturing wells originally stimulated using legacy methods. Refracturing wells plays a vital role in the overall pad-level production strategy and prevents losing parent wells when fracturing child wells. High-resolution acoustic imaging technology has become commonplace for assessing all aspects of the refracture operation. In a single run, this technology captures detailed corrosion and wall loss information to de-risk subsequent refracture injection pressures and rates. While new casing can be assumed to be within API specification of 12.5% from nominal thickness, legacy wells may be up to 20 years old bring no such guarantee, and assets are often exposed to corrosive environments some containing H2S, mechanical wear, and were previously exposed to high-rate slurry. Based on the submillimetric datasets collected, this diagnostic imaging technology informs the critical decisions of whether to run a protective tie-back string, what depth the liner hanger can be safely set at, where Fracture-Driven-Interactions (FDI) communication between neighboring wellbores may have taken place through casing and liner deformation analysis, and provides perforation erosion analysis of the initial stimulations proppant placement. This provides operators with the insight needed to efficiently tailor the refracture program to target undrained reservoir, de-risk any corrosion or deformation concerns from the original casing and reduce the likelihood of total loss of parent wells due to FDI’s.

This paper details how high-resolution acoustic imaging is used to assess pre-refracture well integrity, optimize refracture designs, and increase production rates. From a well-integrity perspective, the asset is inspected for corrosion, ovality, mechanical wear, and connection defects. Using the submillimetric defect dimensions for wall loss events, Effective Area, RSTRENG, Modified B31G, and Barlow burst pressure calculations are conducted to determine the safe pressure envelope of the existing casing. This enables a definitive decision on whether to run a costly tie-back string to protect a damaged or corroded casing from failure during the subsequent stimulation. From a refracture design perspective, the novel imaging technology enables operators to target under-depleted zones for restimulation. Outlying stages with low or non-uniform perforation growth are identified by capturing submillimetric measurements of the initially stimulated perforations. Once identified, these under-stimulated stages can be selectively targeted in the refracture design by adjusting proppant poundage, selecting appropriate diverters, defining mesh sizing, optimizing slurry rates, or altering exit hole area and phase by adding perforations in the same or new orientation phase.

Lastly, this paper contains two field-based case studies outlining real-world deployments of this technology to provide operators with a single-pass evaluation of well integrity and optimize production rates.

Paper Number: SPE-217768-MS

Authors: Trent Pehlke; Greer Simpson; Tamara Maxwell; Charles Bourgeois; Joshua Stibbs

Read the full white paper: “On Track for Refrac: Targeting Under-Stimulated Stages and Assessing Casing Integrity Defects with High-Resolution Acoustic Imaging” to get the whole story.

See also: 2nd paper released at HFTC 2024

SPE-217819-MS: High-Resolution Acoustic Imaging Deployed for Mapping Permanent Fiber Optic Lines