Unlock content

Share this

An established operator sought to verify the design and completion of a well by measuring the fracturing efficiency and the uniformity of proppant distribution throughout the well. HADES-R® assesses proppant distribution post-stimulation by measuring perforation erosional growth. Measuring changes in perforation open flow area requires extremely high-resolution 3D measurements to assess correctly, and this is where DarkVision’s HADES-R® tool provides unparalleled capabilities to evaluate proppant distribution and assess and validate the design of a well.

By directly measuring the area of every perforation at the inner and outer casing surface with DarkVision’s HADES-R®, the operator received a detailed assessment of proppant distribution, uniformity of the proppant per stage, and an assessment of donor and thief stages caused by premature plug failure. This analysis allowed the operator to A/B test various completions designs, slurry rates, and concentrations and optimize all variables pertaining to their frac.

Upon inspection, the operator discovered multiple stages were over-stimulated while other stages were under-stimulated. DarkVision’s high-resolution acoustic data empowered the operator to investigate the root cause and identify plug failures that were not detected during frac operations from surface pressure gauges, and improve subsequent frac procedures.

DarkVision’s HADES-R® tool scanned the entire well and measured all 1060 perforations in a single continuous high-speed pass. This enabled the operator to assess the completion, depth and phase placement of every perforation, isolation and depth of every plug, and identify any wall loss and connection makeup integrity defects all in a single run.

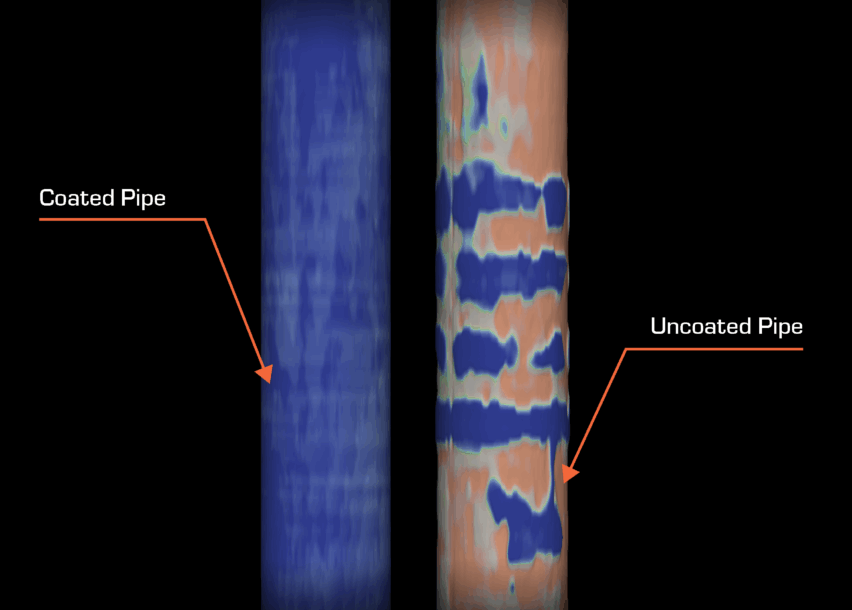

The newest standard in downhole inspection is directly measuring the open hole areas of perforations at the wall ID and OD in 3D. During stimulation, the entry hole expands and rounds over as large volumes of proppant erode through the inner surface edges first before eroding through the perf and gradually growing the exit hole as it leaves the casing.

With DarkVision’s Advanced Entry and Exit Hole Analysis, even when one end of a perforation is obscured or plugged, the perforation can be virtually unplugged by correlating the ratio of the entry-to-exit hole of the population of the perforations in the well or for a specific stage design. This means more perforations are analyzed and no flushing of perforations are required.

DarkVision’s High-resolution 3D Acoustic data provides operators with the most complete and representative understanding of their wells.

Our leading whitepaper goes into further detail. Learn how operators are understanding and quantifying how design choices impact their wells and how they’re reducing the cost of their completion designs while simultaneously optimizing operations.

Watch Greer present the latest paper released at the 2023 SPE/ICoTA Well Intervention Conference & Exhibition.

By clicking Submit you’re confirming that you agree and consent to our Terms and Conditions.