Unlock content

Share this

Montney Formation

HADES-R™

An established Montney operator required quantified orientation data of their permanently installed fiber clamps to ensure that the fiber optic cable could be avoided during perforation operations. To mitigate the risk of perforating through the fiber optic line, DarkVision was brought in to perform a clamp orientation analysis to measure the exact orientation of the fiber with sub-degree resolution.

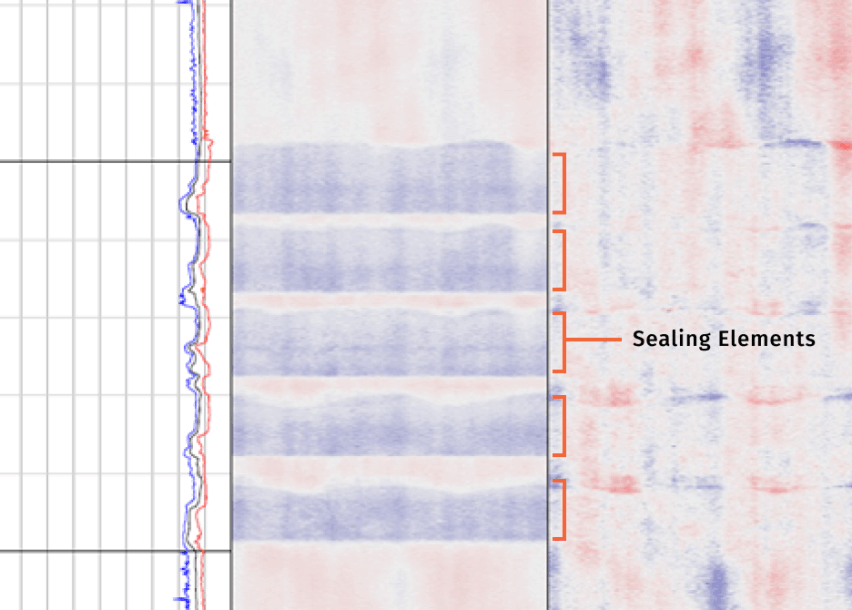

DarkVision’s HADES-R™ tool was deployed to image the well’s 2600m lateral section. Using DarkVision’s proprietary high-resolution acoustic imaging technology to “see through the steel”, each cross-coupling clamp and blast protector location was identified, and the angular orientation measured.

All 60 fiber clamp orientations were measured, signifying a 100% success rate. Images with submillimetric resolution were provided for each location. Using this data, the operator was able to accurately map the fiber optic line and orient their perforations to avoid a potential catastrophic loss of a costly piece of capital equipment. The platform is capable of imaging all standard clamps and backside equipment, including blast protectors, cross-coupling clamps, and centralizers.

HADES-R™ can image a well’s casing and fiber clamps in a single run at a continuous rate of 45 fpm; it does not require station stops at each clamp location. This drastically reduces logging time while simultaneously improving resolution and detection capability. The tool seamlessly integrates into the operators’ well prep operations, resulting in considerably less downtime when compared to legacy methods of clamp detection.

HADES-R™ also has no limitation on deployment method, as opposed to traditional tools that need to be deployed on e-coil or wireline tractor. As a result, an operator can gain significant cost savings from optimized fiber installation timelines, decreased deployment costs, reduced material costs, and minimized logistical and labor expenses.