URTEC-4044732-MS

High-resolution direct 3D acoustic measurements of a casing breach at a plug-set location

Full whitepaper available here: URTEC-4044732-MS: Assessing the Impact of Oriented Perforating Strategies and Frac Plug Performance in DJ Basin Wells Using High-Resolution Acoustic Imaging

Abstract

Chevron utilized high-resolution acoustic imaging in combination with analyzing surface treatment data to assess their completion design and perforating strategies performance in the Denver-Julesburg (DJ) Basin. The multi-well assessment quantified the impact of perforation orientation design, orientation deployment system, and the effectiveness of dissolvable isolation plugs compared to composite plugs in three phases. Two key performance indicators derived from the acoustic imaging technologies measurements of post-fracture perforations and plug sites are used in the assessment, namely cluster efficiency (CE) and uniformity index (UI). The resulting completion design changes yielded a 15% increase in the CE, 13% improvement in UI, and up to a 10% increase in production rates when these changes were correlated with production data.

To complete this three-phase assessment, Chevron selected and deployed high-resolution acoustic imaging technology post-frac and plug drill-out on the coil tubing in six wells. In each phase, a single variable was manipulated to systematically quantify and evaluate the impact of each variable. In the first phase, three wells completed with dissolvable plugs and zipper fractures were imaged to assess the effect orientation design and orientation system have on stimulation performance.

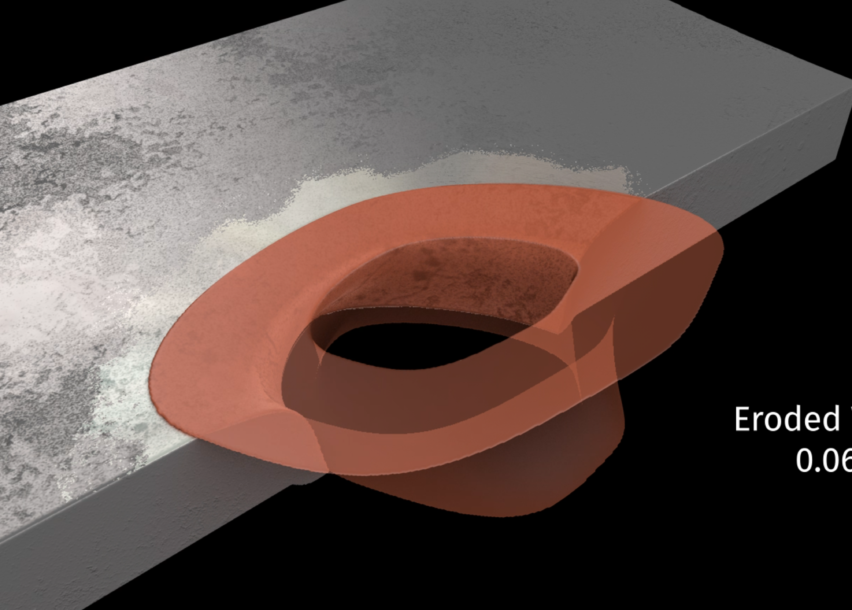

Advanced plug location visualizations generated by the acoustic technology revealed that a high percentage of the dissolvable plugs had failed. Based on these results, a second phase consisting of two wells completed with composite plugs was executed. Composite plugs increased the CE, perforation efficiency (PE), and UI relative to previously deployed dissolvable plugs, with minimal time and cost added to the overall stimulation operations. Finally, a third phase was designed to assess the impact of the perforation orientation on these key performance metrics. In this phase, a single well was completed with a 90° phased nonoriented, 0° (highside) oriented, and 120°/240° orientated perforations that alternated from stage to stage throughout the well using the orientation deployment system discovered in Phase 1.

Chevron iteratively and systematically optimized its stimulation design by analyzing the submillimetric three-dimensional (3D) point cloud of data at each perforation quantified by the acoustic technology, in combination with surface treatment information. The data collected through this assessment quantify the improvements of oriented perforating on perforation size consistency and isolation reliability. The result was a significant improvement in completion performance across key metrics. CE improved from 70% to 85% (+15%), and the UI increased from 67% to 80% (+13%). Therefore, this paper highlights the implementation of a systematic completion design optimization program evaluated using acoustic imaging and surface treatment data.

Paper Number: URTEC-4044732-MS

Authors: Matt Paradeis; Tamara Maxwell; Trent Pehlke; Lydia Richley; Greer Simpson

Read the full white paper: “Assessing the Impact of Oriented Perforating Strategies and Frac Plug Performance in DJ Basin Wells Using High-Resolution Acoustic Imaging” to get the whole story.