Volumetric perforation erosion analysis presents a novel technique for assessing completion design performance in horizontal wells.

This method builds on established perforation erosion analysis to capture more information and complexity by analyzing the full volume of metal loss during hydraulic stimulation. In 2023, Occidental Petroleum (OXY) performed a side-by-side comparison of volumetric perforation erosion analysis and permanent fiber optics by using both methods to assess completion designs in a single hydraulically fractured well.

Permanent fiber optics have the benefit of providing real time data at the cluster level but are costly and vulnerable to mechanical failure. Volumetric perforation erosion analysis provides a snapshot in time, but is more affordable, less prone to mechanical failure and operational issues.

In general, the study found that there was nearly 1:1 agreement between volumetric perforation erosion and permanent fiber optics, suggesting that operators can get results close to those offered by permanent fiber optic at a fraction of the cost. The full results of this study are available on OnePetro.

The Evolution of Perforation Erosion

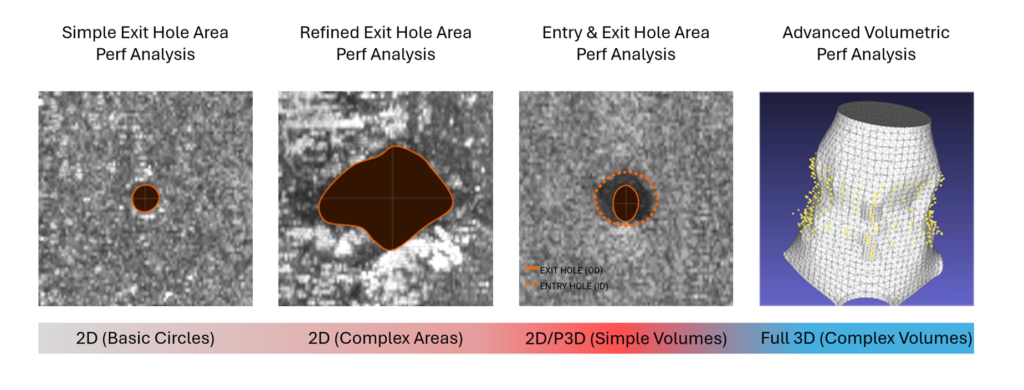

The evolution of perforation erosion analysis has been based on two foundational technological advancements. First, the introduction of high-resolution acoustic imaging that was capable of directly measuring perforations very precisely (0.25mm resolution) and in 3D space. This allows for very accurate measurements, and for the tunnel of the perforation, between the ID and OD of the casing, to be accurately captured.

Secondly, over time, DarkVision amassed a library of over 300,000 perforations captured using high-resolution acoustic imaging. This data could be analyzed for trends and outliers, and refinements to perforation erosion analysis could be implemented to address scenarios where ‘exit hole only’ analysis meant that perforations were inadequately evaluated.

When perforation erosion analysis was first introduced, perforations were assessed as a basic shape with an equivalent circular diameter. Data began revealing anomalies like elongated or keyhole perforations like those often found in the heel clusters of stages, and perforations that were significant outliers in growth, such as the ones shot through connections. These observations led to a transition from simple circular metrics to measurements that more accurately captured the 2D area of the perforation at the casing’s outer diameter (OD), greatly improving accuracy and reliability.

Analysis of this large volume of data highlighted scenarios that were not sufficiently addressed by analyzing perforations as complex 2D shapes, including scenarios where the exit hole didn’t appear to grow. Adding measurements of the entry hole of the perforation, along the casing inner diameter (ID), to the analysis, further improved accuracy and reliability. Perforation erosion was clearly a 3D issue, rather than a 2D one: erosion of the entire volume needed to be considered.

Advancements in the software and machine learning models for analyzing perforations have now made volumetric perforation erosion analysis at a commercial scale feasible. The volumetric approach captures the most nuance and complexity, providing the most accurate and reliable information to date.

How Volumetric Perforation Erosion is Calculated

The Linear Approximation Method

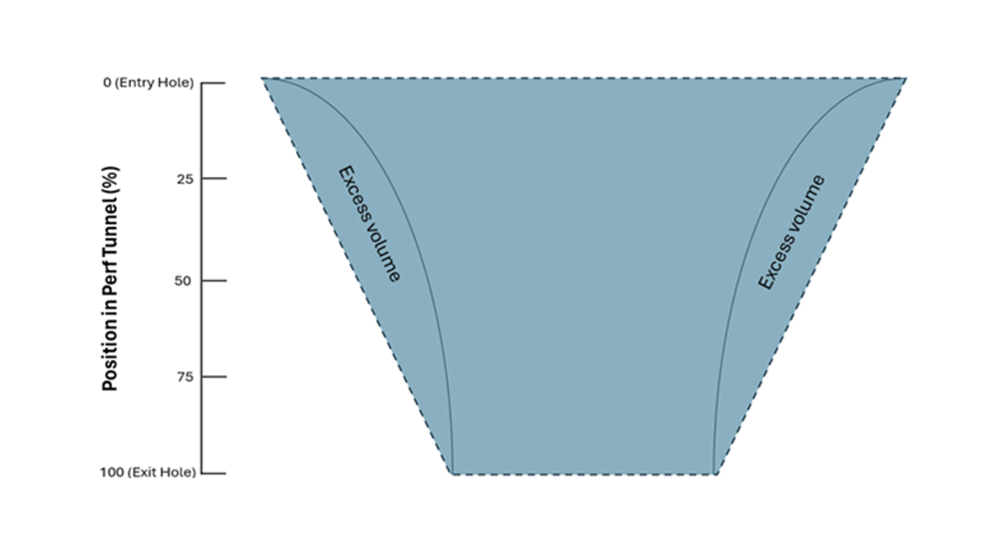

A very basic approximation of volumetric erosion can be performed by measuring the perforation entry hole and exit hole and assuming a direct line between them. This method does not account for the curvature pattern of the erosion and will systematically overestimate the volume of metal eroded from the casing.

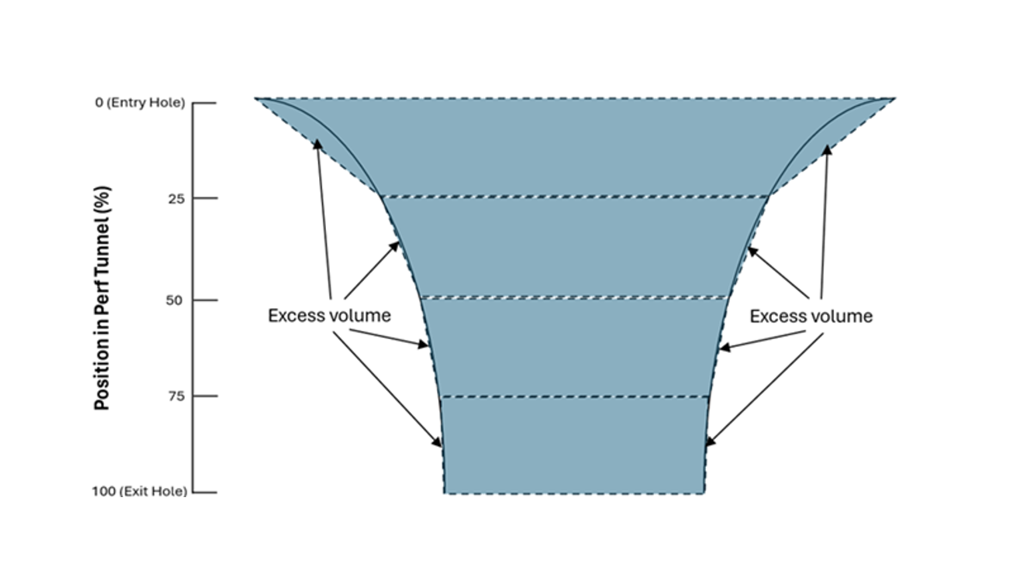

To come up with a closer representation of the volume of metal eroded, additional measurements are required along the casing. It was determined that three additional measurements made at specific locations provided a sufficiently accurate measurement of volume loss.

Machine Learning Method

The most advanced method involves combining the 3D point cloud of data captured by high resolution acoustic imaging with machine learning models to generate the volume of erosion.

The Test Well

Oxy completed a horizontal well in the Powder River Basin that was equipped with permanent fiber optics for Distributed Acoustic Sensing (DAS) and Distributed Temperature Sensing (DTS) data collection during stimulation. They also performed high-resolution acoustic imaging after the post-frac cleanout was complete to collect the data for volumetric perforation erosion analysis.

They were interested in testing the performance of two different perforating charge types: standard deep penetrator used in the multi-perf cluster (MPC) stages and “big-hole” charges used in single-perf cluster (SPC) stages. The performance of each design was evaluated with both permanent fiber optic and volumetric perforation erosion analysis, and the results of the methods compared.

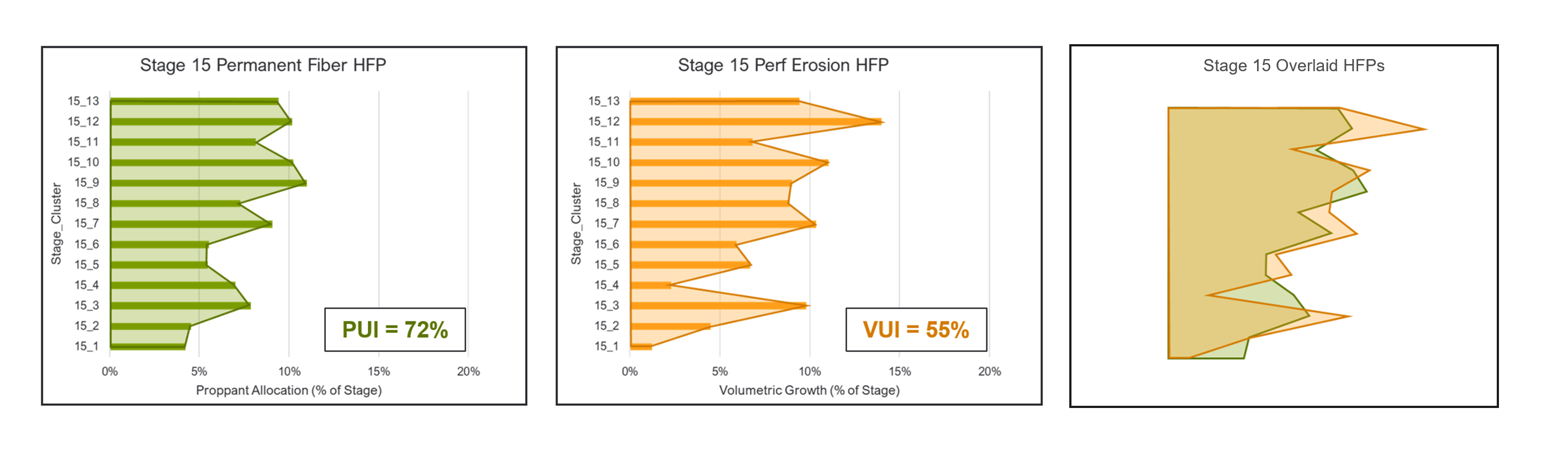

Overall, the two methods had near 1:1 agreement. They showed similar trends and came to the same conclusions when ranking the relative performance of each design option. Both diagnostic methods indicated an uplift in Stimulation Distribution Efficiency (SDE) when changing from MPC to SPC designs.

By comparing the HFPs above, both analyses indicate similar trends in treatment bias and proppant distribution. Fiber is used to estimate proppant placement based on relative acoustic intensity during stimulation. While it does not measure proppant passing through a perforation directly, it is a good indicator of slurry placement. Perforation erosion analysis is a measurement of erosion through a specific perforation, which is influenced by proppant concentration, particle mass, particle velocities, and a multitude of other parameters. Based on the difference in measurement theories, it is entirely possible that dominant clusters may vary slightly from different diagnostic methodologies. Further stages are compared in the paper.

Impact of the Findings

Volumetric perforation erosion analysis provides results similar to fiber at a fraction of the cost, with greater flexibility. Given its cost effectiveness, operators have the option to analyze a greater number of wells using this method.

The full results of this study are detailed in “Adding Depth: The Superiority of Volumetric Perforation Erosion Analysis for Evaluating Stimulation Performance and Optimizing Completion Designs” which was presented at the Hydraulic Fracturing Technology Conference in February 2025.

Paper Number: SPE-223542-MS

Authors: Matt Jones; Charles Bourgeois; Trent Pehlke; Anthony Battistel; Cole Coupland; Gaurav Handa; Jon Nilemo; Kenneth Tan.

Read the full white paper: “Adding Depth: The Superiority of Volumetric Perforation Erosion Analysis for Evaluating Stimulation Performance and Optimizing Completion Designs” to get the whole story.