DarkVision’s first SPE paper!

DarkVision released its first SPE paper with co-authors Jagged Peak, PETRONAS Canada, and Encana Oil & Gas (USA). The paper, SPE-199718, is revered for being the most comprehensive overview of perforation erosion analysis across all North American basins. Pulling from a database of over 30,000 perforations measured by DarkVision’s HADES platform, the paper showcases how operators are using high-resolution acoustic imaging to improve their completions programs.

Want to learn more? Read “Acoustic Imaging of Perforation Erosion in Hydraulically Fractured Wells for Optimizing Cluster Efficiency“.

Want to see the database of 30,000 perforations? Check out the full paper here.

Abstract

A new solid-state, high-resolution acoustic imaging technology has been applied in hydraulically fractured wells to image and quantify perforation erosion. The downhole device captures detailed full-lateral logs of horizontal wells, without the need for clear fluids to facilitate measurements. This paper discusses how the imaging technology functions, lab testing that validated the measurements, and field testing completed with several operators in a variety of reservoirs and basins.

This high-resolution, acoustic-based downhole imaging technology provided a 360-degree view inside a variety of wells. Instead of optics, the imaging technology used high-frequency sound waves to image a full lateral through opaque fluids at sub-millimetric levels. The imaging tool was conveyed on either tractor or e-coil to continuously log the wellbore between 15 and 30ft/min, completing a full azimuthal scan that imaged individual perforations regardless of orientation. A range of imaging techniques quantified and measured each perforation to determine the extent of erosion in each perforation, cluster, and stage sustained during the hydraulic fracturing process.

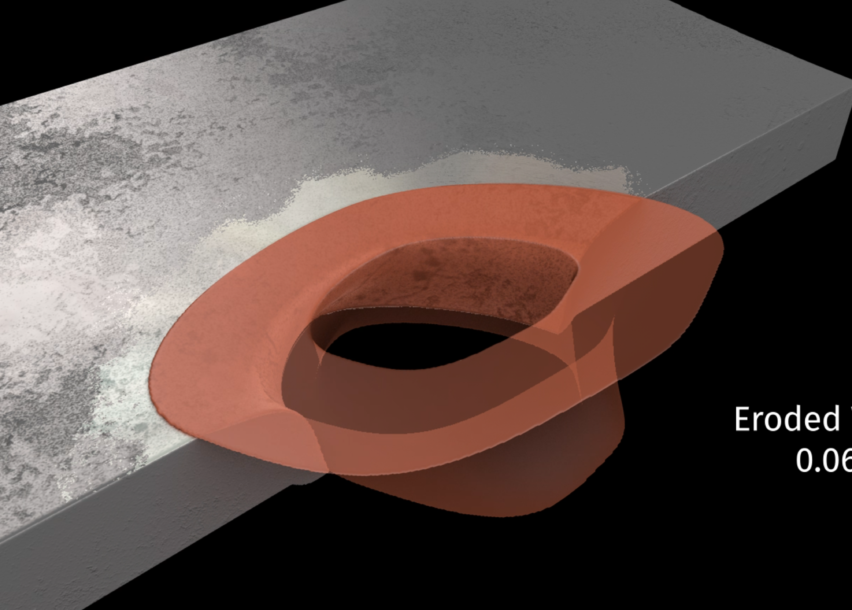

The acoustic imaging technology was initially tested in the lab with calibration jigs and perforated pipe samples to validate its accuracy. The technology was then field deployed by several operators and used to assess perforation erosion in extended horizontal wells by scanning the entire well from toe to heel and measuring thousands of perforations in a single log. The data gathered quantified the perforation diameter, perforation erosion range, perforation orientation dependency, cluster efficiency, perforation erosion bias, and discovered the presence of significant casing damage around areas where plugs were set. The image results showed the distribution, size, and measured diameter for each perforation in each cluster. The results noted toe or heel biases and how these changed in different well types and designs in different basins. The data allowed operators to reach conclusions regarding erosion and cluster efficiency across the entire lateral in various wells in the Montney, Permian, and Anadarko basins. Wells across North America were scanned in several other basins for comparison purposes using various completion designs from different operators.

The high-resolution acoustic imaging technology offers a robust 360-degree view of long horizontal wells and perforation measurements post-fracture. Over 35,000 perforations have been measured using the technology in the field across various well types with different designs. The technology has proven to be a valuable tool in improving and optimizing completion designs by providing detailed feedback on where designs are working effectively and where they can be improved.