With resolutions down to 0.01″, DarkVision’s technology is finding phenomena that have previously gone undetected in industry. At URTeC 2021, DarkVision released its latest findings on how perforations grow after being subjected to (literal) tonnes of sand and fluid. The paper challenges long-held ideas around concentric hole growth and showcases obscurely-shaped perforations from a database that has eclipsed 80,000 perforations at the time of writing.

Check out our whitepaper “High-Resolution Acoustic Imaging for Geometric Quantification of Eroded Perforations in Hydraulically Fractured Wells” for more information.

Get a copy of the full whitepaper here.

Abstract

Advanced solid-state acoustic imaging technology has been deployed in hydraulically fractured horizontal wells capturing three-dimensional, sub-millimetric measurements of over 80,000 perforations. This paper provides laboratory validation of the area analysis methodology for perforation erosion assessment; notable trends pertaining to post-stimulation perforation growth, shape, and geometry; and unique patterns of casing damage mechanisms that are frequently observed at specific perforation cluster locations.

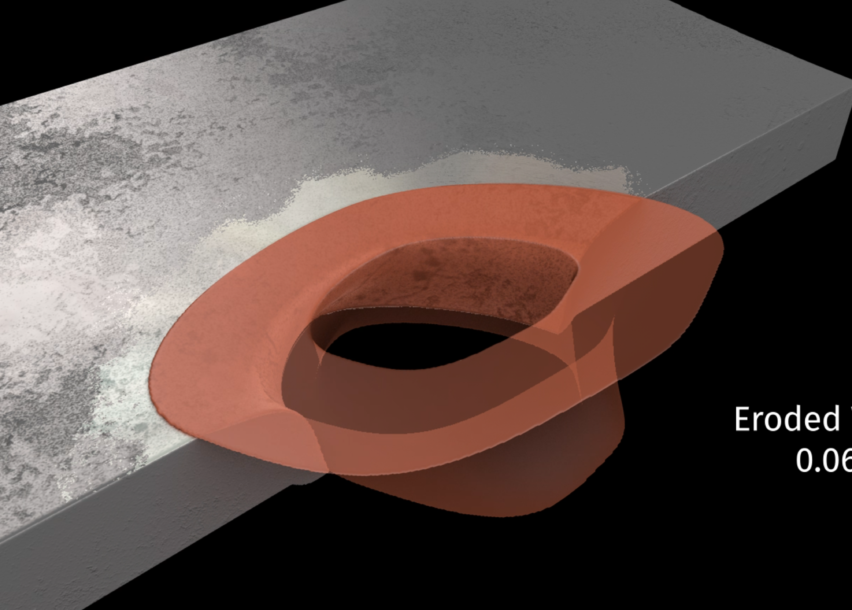

This paper explores the underlying assumptions of perforation circularity. The analysis highlighted that a proportion of stimulated perforations did not align with perfect circularity assumptions commonly assumed in coefficient of discharge and pressure drop calculations.

An analysis of perforations that exhibit a “keyhole” shape, where a narrow erosional path grows toward the toe of the stage, was conducted. Keyhole perforations occur more frequently in the heel end of a stage and may be an indicator of uneven proppant distribution. Perforation aspect ratio (ratio of length to width) is also discussed and is shown to be correlated with the location of the perforation within a stage.

Perforations shot through casing connections are reviewed, with aggregated damage statistics indicating major differences in damage severity between premium and non-premium connection types. A particular pattern of casing damage consistently located at a phasing of 180 degrees relative to the heel-most perforations in a stage is also examined and several possible contributing factors are discussed.

The data presented provides a foundation for furthering industry’s understanding of how perforation geometry changes throughout the hydraulic fracturing program and when shape considerations should be accounted for when determining cluster efficiency, pressure drop, and coefficient of discharge in hydraulically fractured wells.

Interested in joining the team responsible for generating industry-first whitepapers? Check out our Careers Page for more details.