Unlock content

5 key questions to ask prior to a refrac

Share this

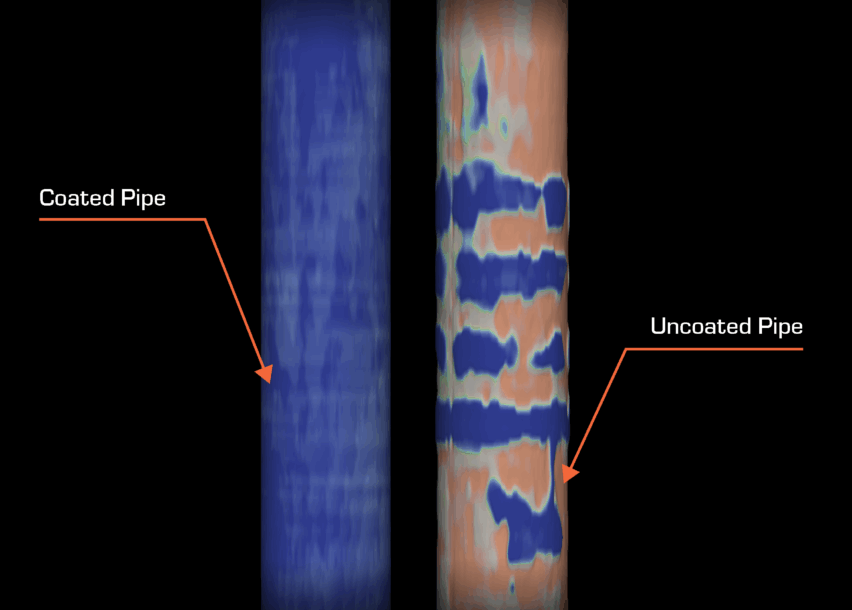

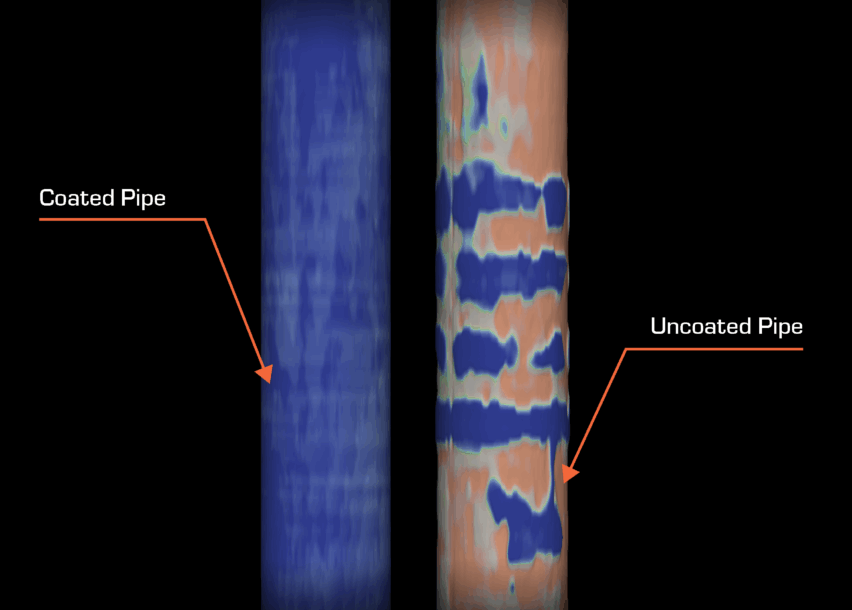

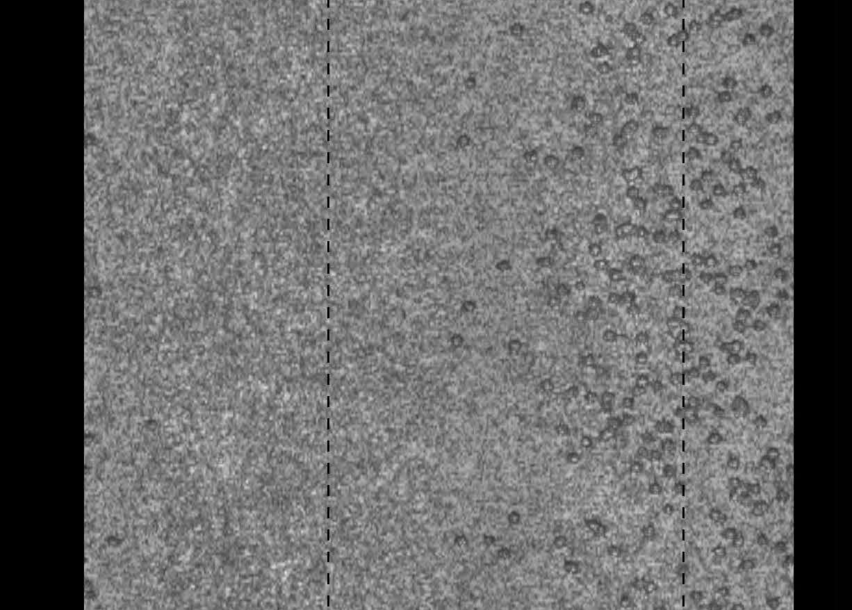

Conventional tools have been falling short of providing operators with a holistic integrity assessment of their wells. Now, with acoustic imaging, operators are gaining a significant step-change in resolution, accuracy, and ability to evaluate their wells for integrity risks. Operators are making better-informed decisions, determining if protective measures are needed, screening candidate wells, and optimally planning refrac operations with acoustic imaging.

Acoustic imaging can help operators answer key questions that will inform their refrac strategy:

| What is the condition of the well? Are there any limiting defects? | As part of understanding the integrity of a well, a host of defects can be detected. For example, casing connections, ID/OD corrosion, mechanical damage and ovality can all impact the success of a refrac. Acoustic imaging delivers complete circumferential imaging of tubing, casing and connections to eliminate the blind spots of legacy technologies like calipers and cameras. |

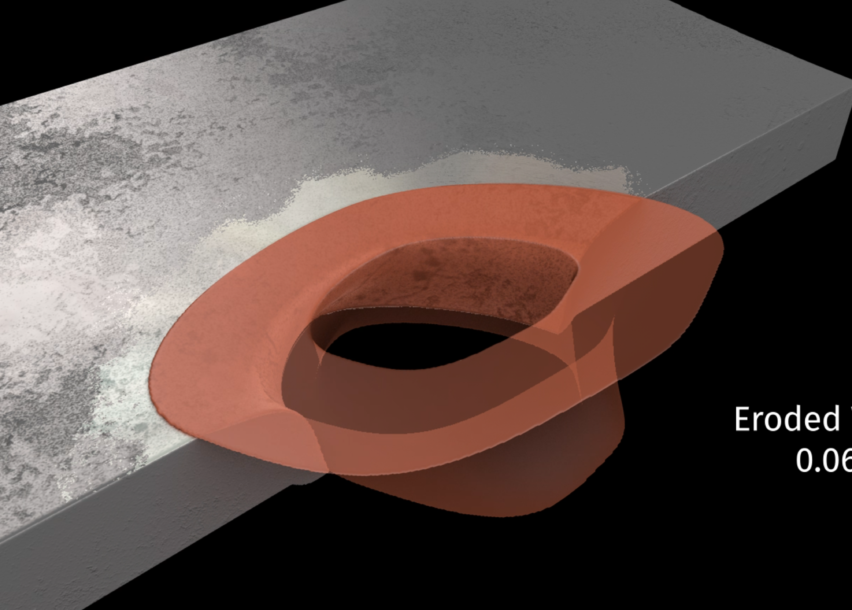

| Can the well handle the pressure? | Calculating the ideal refrac pressure requires clearly understanding well conditions. The most representative estimate comes from using an Effective Area calculation based on the riverbottom profile of a casing joint. Using Effective Area calculations results in less conservative upper limits for burst pressure, creating an opportunity to maximize refrac operations. |

| What is the optimum depth for a liner assembly? | Acoustic imaging helps identify the ideal liner hanger placement to ensure a good seal and ensure proper isolation. Placing the liner hanger assembly over corroded or damaged casing can result in fluid bypass channels that lead to breached casing, damaged liner hangers, or even a total loss of the well. |

| Is a tieback string needed? | A burst pressure analysis may determine that a well with significant integrity issues can still be safely refractured with the use of a protective tieback string. If the integrity issues are less severe, it may be possible to complete refracture without this costly equipment. |

| Should you walk away? | It may not always be economical to refracture the well. Well integrity analysis integrated into refracture work planning can help avoid the costs and impacts of failed refracs, while maximizing good opportunities. |

An operator turned to DarkVision to perform a thorough well integrity investigation and burst pressure analysis to assess refracturing the well without a frac string.

DarkVision’s HADES-T® and HADES-R® high-resolution acoustic imaging system scanned all 290+ joints and inspected the casing for ID and OD defects. Due to the high-resolution coverage of the defects, DarkVision was able to use an Effective Area calculation to get the most representative estimate of burst pressure. This Effective Area calculation revealed a threshold of 11,954 psi whereas a Barlow (less representative) calculation established a much more conservative burst pressure of 5716 psi.

Based on the detailed report from DarkVision, the operator evaluated every defect and the maximum safe re-frac pressure to determine that a re-frac string was not needed. Additionally, the operator was able to de-risk the re-frac operation and safely operate 6,000psi higher across this joint without compromising the integrity of the well.

Ready to optimize your refrac? Get in touch

Unlock content

Unlock content

Unlock content

Unlock content